100% Original Factory Pipe Insulation - 40mm thickness rubber foam insulation sheet – Kingflex

100% Original Factory Pipe Insulation - 40mm thickness rubber foam insulation sheet – Kingflex Detail:

Advantages

Standard Dimension

|

Kingflex Dimension |

|||||||

|

Thickness |

Width 1m |

Width 1.2m |

Width 1.5m |

||||

|

Inches |

mm |

Size(L*W) |

㎡/Roll |

Size(L*W) |

㎡/Roll |

Size(L*W) |

㎡/Roll |

|

1/4″ |

6 |

30 × 1 |

30 |

30 × 1.2 |

36 |

30 × 1.5 |

45 |

|

3/8″ |

10 |

20 × 1 |

20 |

20 × 1.2 |

24 |

20 × 1.5 |

30 |

|

1/2″ |

13 |

15 × 1 |

15 |

15 × 1.2 |

18 |

15 × 1.5 |

22.5 |

|

3/4″ |

19 |

10 × 1 |

10 |

10 × 1.2 |

12 |

10 × 1.5 |

15 |

|

1″ |

25 |

8 × 1 |

8 |

8 × 1.2 |

9.6 |

8 × 1.5 |

12 |

|

1 1/4″ |

32 |

6 × 1 |

6 |

6 × 1.2 |

7.2 |

6 × 1.5 |

9 |

|

1 1/2″ |

40 |

5 × 1 |

5 |

5 × 1.2 |

6 |

5 × 1.5 |

7.5 |

|

2″ |

50 |

4 × 1 |

4 |

4 × 1.2 |

4.8 |

4 × 1.5 |

6 |

Technical Data Sheet

|

Kingflex Technical Data |

|||

|

Property |

Unit |

Value |

Test Method |

|

Temperature range |

°C |

(-50 – 110) |

GB/T 17794-1999 |

|

Density range |

Kg/m3 |

45-65Kg/m3 |

ASTM D1667 |

|

Water vapor permeability |

Kg/(m.s.pa) |

≤0.91×10 ﹣¹³ |

DIN 52 615 BS 4370 Part 2 1973 |

|

μ |

- |

≥10000 |

|

|

Thermal Conductivity |

W/(m.k) |

≤0.030 (-20°C) |

ASTM C 518 |

|

≤0.032 (0°C) |

|||

|

≤0.036 (40°C) |

|||

|

Fire Rating |

- |

Class 0 & Class 1 |

BS 476 Part 6 part 7 |

|

Flame Spread and Smoke Developed Index |

|

25/50 |

ASTM E 84 |

|

Oxygen Index |

|

≥36 |

GB/T 2406,ISO4589 |

|

Water Absorption,%by Volume |

% |

20% |

ASTM C 209 |

|

Dimension Stability |

|

≤5 |

ASTM C534 |

|

Fungi resistance |

- |

Good |

ASTM 21 |

|

Ozone resistance |

Good |

GB/T 7762-1987 |

|

|

Resistance to U.V. and weather |

Good |

ASTM G23 |

|

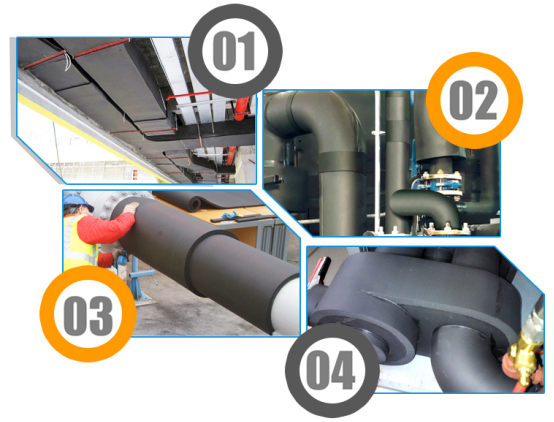

Application

1. Insulation of workshop and building

2. Air conditioning units

3. Sound insulation/absorption system

4. Protection of sports equipment, in cushions and diving suits

5. Every kind of cold/hot medium containers

6. high lustration environments of tobacco, medicine, electronic, car, foodstuff industry

company

40+ Years of Military&Industrial Experience

As one of the major manufacturers of rubber and silicone products, Kingflex Insulation Company has been providing high-quality products and excellent services for customers worldwide. With 40+ years of experience in the industry and through our hard work, our products have won an excellent international reputation.

Independent R&D and QC Team Capabilities

Aside from standard types in stock, we can also offer design and sampling services for your nonstandard OEM needs.

Well-equipped with Molding, Extrusion and Foaming Facilities

We specialize in rubber foam insulation products for HVAC, building and many other industries. Our production is facilitated with advanced molding, extrusion and foaming equipment.

International Certifications and Markets

Manufactured under strict QC procedures, our products meet ROHS, REACH, SGS, BS, CE, DIN, UL 94 tests. Our products are exported to Europe, North America, Southeast Asia and other areas.

OUR CUSTOMERS

Production Process

We are sticking to developing advanced technologies in order to meet the gradually arise new demands from industries of chemical engineering, mechanical, electronics, auto, construction, pharmaceutical etc.. Worldwide importers, wholesalers, distributors are Welcome to visit our factories and discuss long-term partnership. Your gracious comments will be our fresh motivation and encouragement to driving us to be top supplier in this world.

Product detail pictures:

Related Product Guide:

The organization upholds the philosophy of "Be No.1 in good quality, be rooted on credit history and trustworthiness for growth", will keep on to provide previous and new customers from home and overseas whole-heatedly for 100% Original Factory Pipe Insulation - 40mm thickness rubber foam insulation sheet – Kingflex , The product will supply to all over the world, such as: Spain, Frankfurt, Cyprus, We take measure at any expense to achieve essentially the most up-to-date equipment and approaches. The packing of nominated brand is our a further distinguishing feature. The items to assure years of trouble-free service has attracted a great deal customers. The solutions are obtainable in improved designs and richer assortment, they're created scientifically of purely raw supplies. It readily available in a variety of designs and specifications for your selection. The most recent kinds are a great deal better than the preceding one particular and they are quite popular with lots of prospects.

In general, we are satisfied with all aspects, cheap, high-quality, fast delivery and good procuct style, we will have follow-up cooperation!

Product categories

-

Phone

-

E-mail

-

Whatsapp