Best quality Interior Wall Insulation - Rock Wool Insulation Boad – Kingflex

Best quality Interior Wall Insulation - Rock Wool Insulation Boad – Kingflex Detail:

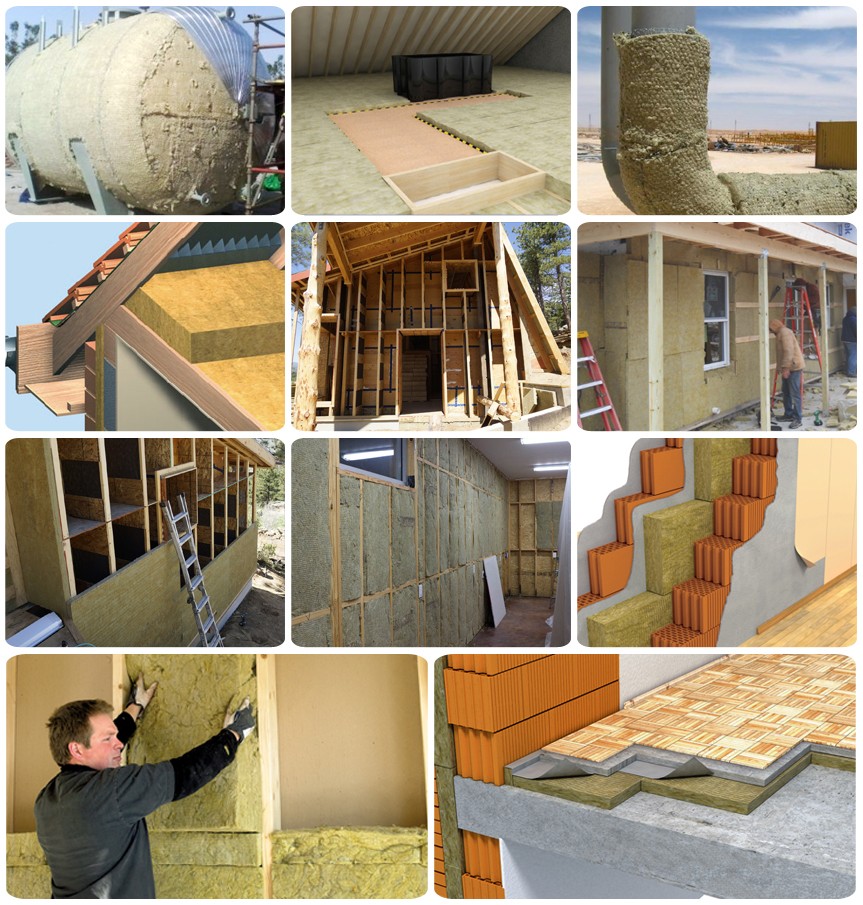

Kingflex rock wool insulation board is mainly used for external wall. It is together with the roof, form the envelope of any building, protecting everyone and everything inside.

They also cover the largest surface area, making them a prime area for preventing heat loss. The main place where heat is lost is by escaping through poorly insulated walls.

|

Technical indicators |

technical performance |

Remark |

|

Thermal conductivity |

0.042w/m.k |

Normal temperature |

|

Slag inclasion content |

<10% |

GB11835-89 |

|

No-combustible |

A |

GB5464 |

|

Fiber diameter |

4-10um |

|

|

Service temperature |

-268-700℃ |

|

|

Moisture rate |

<5% |

GB10299 |

|

Tolerance of density |

+10% |

GB11835-89 |

With Kingflex rock wool insulation board, living spaces can be made warm, energy efficient and compliant with modern building standards – as well as gaining additional benefits in terms of acoustics, indoor comfort and fire safety.

Discover the importance of insulation for exterior walls, and the positive impacts it can bring. have many advantages such as light weight, good performance as a whole and low coefficient of heat conductivity. They are widely used in construction and other industries in heat preservation field. It also has a good function of sound absorption, so it can be used to reduce the industrial noise and deal with the sound absorption in building.

Kingflex rock wool is produced with natural basalt as main material, melted in high temperature and made into artificial abio-fibers by high speed centrifugal equipment, then added with special agglomerates and dust-proof oil, heated and solidified into various rock wool heat preservation products in different specifications according to different requirements.

| Rock wool boards water-proof rock wool boards | ||

| size | mm | length 100 width 630 thick 30-120 |

| density | kg/m³ | 80-220 |

Application

Kingflex rock wool insulation board is central to developing energy-efficient walls, and meets modern code requirements by providing continuous insulation for residential, commercial and industrial buildings.

Product detail pictures:

Related Product Guide:

It adheres on the tenet "Honest, industrious, enterprising, innovative" to acquire new solutions continuously. It regards prospects, success as its personal success. Let us build prosperous future hand in hand for Best quality Interior Wall Insulation - Rock Wool Insulation Boad – Kingflex , The product will supply to all over the world, such as: Indonesia, Johannesburg, Honduras, We've been adhering to the philosophy of "attracting customers with the best items and excellent service". We welcome customers, business associations and friends from all parts of the world to contact us and seek cooperation for mutual benefits.

We feel easy to cooperate with this company, the supplier is very responsible, thanks.There will be more in-depth cooperation.

Product categories

-

Phone

-

E-mail

-

Whatsapp