China Supplier Pipe Insulation And Cladding - Rubber plastic plate – Kingflex

China Supplier Pipe Insulation And Cladding - Rubber plastic plate – Kingflex Detail:

Product Description

The rubber foam products of our company are produced by imported high-end technology and automatic continuous equipment. We have developed a rubber foam insulation material with excellent performance through in-depth research. The major raw materials we use are NBR/PVC.

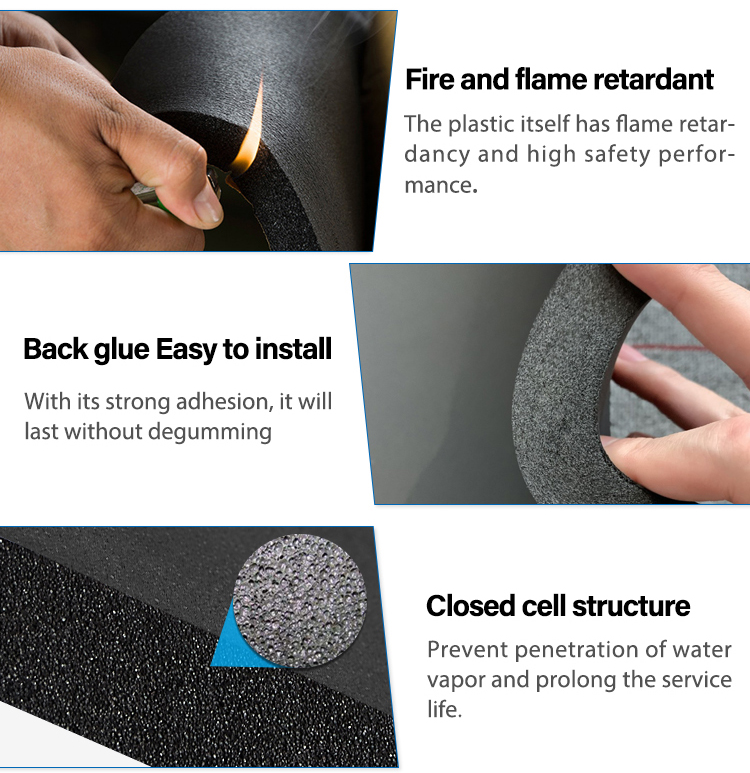

The main characteristics are: low density, close and even bubble structure, low thermal conductivity, cold resistance, extremely low water vapor transmissibility, low water absorbtive capacity, great fireproof performance, superior anti-age performance, good flexibility, stronger tear strength, higher elasticity, smooth surface, no formaldehyde, shock absorption, sound absorption, easy to install. The product is suitable for a wide range of temperature from -40℃ to 120℃.

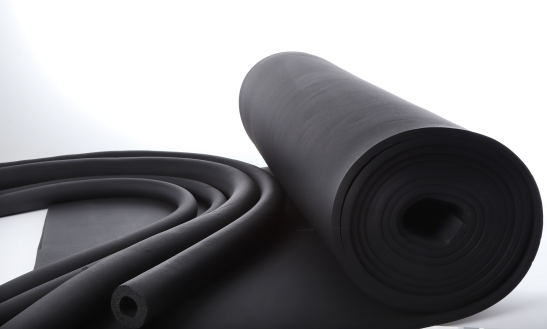

Our Class0/1 insulation is generally black in color, other colors are available upon request. The product comes in tube, roll and sheet form. The extruded flexible tube are specially designed to fit the standard diameters of copper, steel and PVC piping. Sheets are available in standards pre-cut sizes or in rolls.

Product features

Standard Dimension

|

c |

|||||||

|

Thickness |

Width 1m |

Width 1.2m |

Width 1.5m |

||||

|

Inches |

mm |

Size(L*W) |

㎡/Roll |

Size(L*W) |

㎡/Roll |

Size(L*W) |

㎡/Roll |

|

1/4″ |

6 |

30 × 1 |

30 |

30 × 1.2 |

36 |

30 × 1.5 |

45 |

|

3/8″ |

10 |

20 × 1 |

20 |

20 × 1.2 |

24 |

20 × 1.5 |

30 |

|

1/2″ |

13 |

15 × 1 |

15 |

15 × 1.2 |

18 |

15 × 1.5 |

22.5 |

|

3/4″ |

19 |

10 × 1 |

10 |

10 × 1.2 |

12 |

10 × 1.5 |

15 |

|

1″ |

25 |

8 × 1 |

8 |

8 × 1.2 |

9.6 |

8 × 1.5 |

12 |

|

1 1/4″ |

32 |

6 × 1 |

6 |

6 × 1.2 |

7.2 |

6 × 1.5 |

9 |

|

1 1/2″ |

40 |

5 × 1 |

5 |

5 × 1.2 |

6 |

5 × 1.5 |

7.5 |

|

2″ |

50 |

4 × 1 |

4 |

4 × 1.2 |

4.8 |

4 × 1.5 |

6 |

Technical Data Sheet

|

Kingflex Technical Data |

|||

|

Property |

Unit |

Value |

Test Method |

|

Temperature range |

°C |

(-50 – 110) |

GB/T 17794-1999 |

|

Density range |

Kg/m3 |

45-65Kg/m3 |

ASTM D1667 |

|

Water vapor permeability |

Kg/(m.s.pa) |

≤0.91×10 ﹣¹³ |

DIN 52 615 BS 4370 Part 2 1973 |

|

μ |

- |

≥10000 |

|

|

Thermal Conductivity |

W/(m.k) |

≤0.030 (-20°C) |

ASTM C 518 |

|

≤0.032 (0°C) |

|||

|

≤0.036 (40°C) |

|||

|

Fire Rating |

- |

Class 0 & Class 1 |

BS 476 Part 6 part 7 |

|

Flame Spread and Smoke Developed Index |

|

25/50 |

ASTM E 84 |

|

Oxygen Index |

|

≥36 |

GB/T 2406,ISO4589 |

|

Water Absorption,%by Volume |

% |

20% |

ASTM C 209 |

|

Dimension Stability |

|

≤5 |

ASTM C534 |

|

Fungi resistance |

- |

Good |

ASTM 21 |

|

Ozone resistance |

Good |

GB/T 7762-1987 |

|

|

Resistance to U.V. and weather |

Good |

ASTM G23 |

|

Application

Rubber and Plastic insulation materials are widely in multiple scenes for thermal insulation and noise reduction, which are used in various pipes and equipment, such as central air conditioning, air conditioning units, construction, chemical, medicine, electrical appliances, aerospace, auto industry, thermal power etc.

Certification

Rubber foam heat insulation material of our company has obtained FM and ASTM certification of the US, BS476 part 6 & part 7, and ISO14001, ISO9001, OHSAS18001 certificate etc.

Product detail pictures:

Related Product Guide:

Often customer-oriented, and it's our ultimate target to become not only probably the most reputable, trustable and honest provider, but also the partner for our customers for China Supplier Pipe Insulation And Cladding - Rubber plastic plate – Kingflex , The product will supply to all over the world, such as: Denmark, UK, Cyprus, They're durable modeling and promoting effectively all over the world. Under no circumstances disappearing major functions in a quick time, it's a really should in your case of excellent good quality. Guided by the principle of "Prudence, Efficiency, Union and Innovation. the company make a terrific efforts to expand its international trade, raise its company profit and raise its export scale. We're confident that we've been planning to possess a vibrant prospect and to be distributed all over the world within the years to come.

A good manufacturers, we have cooperated twice, good quality and good service attitude.

Product categories

-

Phone

-

E-mail

-

Whatsapp