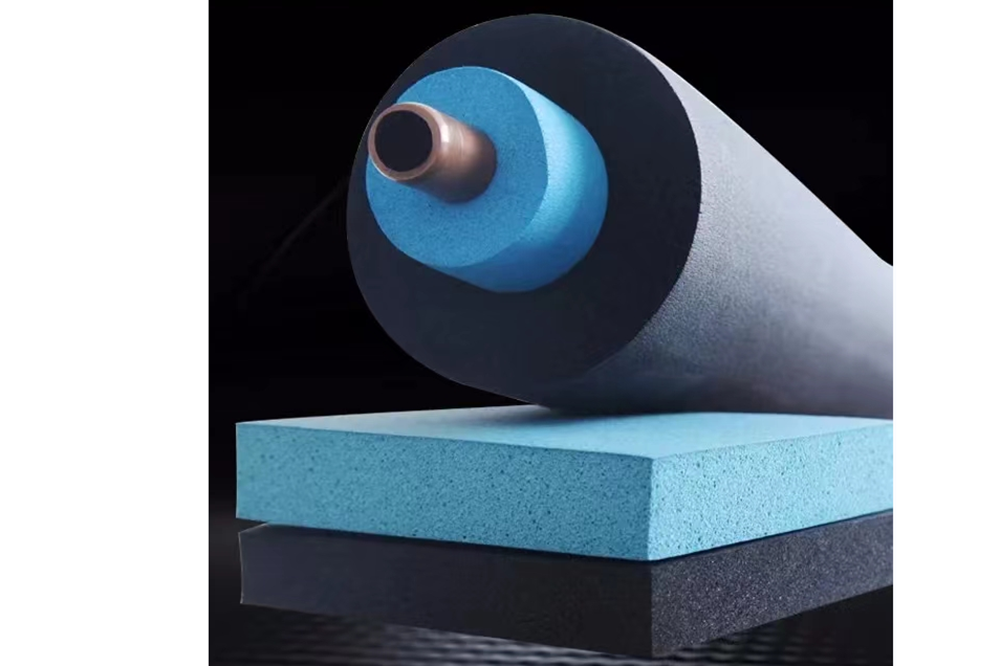

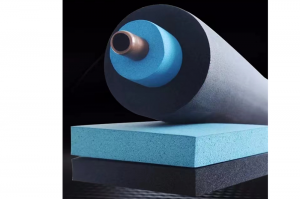

Closed Cell Rubber Foam Insulation For the Cryogenic Equipment Systems

Description

Kingflex Cryogenic Rubber Foam is highly durable and resistant to wear and tear. It is resistant to moisture, chemicals, and UV radiation, making it suitable for use in both indoor and outdoor environments.

Standard Dimension

|

Kingflex Dimension |

|||

|

Inches |

mm |

Size(L*W) |

㎡/Roll |

|

3/4" |

20 |

10 × 1 |

10 |

|

1" |

25 |

8 × 1 |

8 |

Technical Data Sheet

|

Main Property |

Base material |

Standard |

|

|

Kingflex ULT |

Kingflex LT |

Test Method |

|

|

Thermal Conductivity |

-100°C, 0.028 -165°C, 0.021 |

0°C, 0.033 -50°C, 0.028 |

ASTM C177

|

|

Density Range |

60-80Kg/m3 |

40-60Kg/m3 |

ASTM D1622 |

|

Recommend Operation Temperature |

-200°C to 125°C |

-50°C to 105°C |

|

|

Percentage Of Close Areas |

>95% |

>95% |

ASTM D2856 |

|

Moisture Performance Factor |

NA |

<1.96x10g(m.m.Pa) |

ASTM E 96 |

|

Wet resistance Factor μ |

NA |

>10000 |

EN12086 EN13469 |

|

Water Vapor Permeability Coefficient |

NA |

0.0039g/h.m2 (25mm thickness) |

ASTM E 96 |

|

PH |

≥8.0 |

≥8.0 |

ASTM C871 |

|

Tensile Strength Mpa |

-100°C, 0.30 -165°C, 0.25 |

0°C, 0.15 -50°C, 0.218 |

ASTM D1623 |

|

Comprssive Strength Mpa |

-100°C, ≤0.3 |

-40°C, ≤0.16 |

ASTM D1621 |

Main Advantages of product

. Insulation that maintains its flexibility at very low temperatures down to -200℃ to +125℃.

. Reduces the risk of corrosion under insulation

. Protects against mechanical impact and shock.

. Low thermal conductivity

. Low glass transition temperature

. Easy installation even for complex shapes.

Our Company

Company exhibition

Certificate

Product categories

-

Phone

-

E-mail

-

Whatsapp