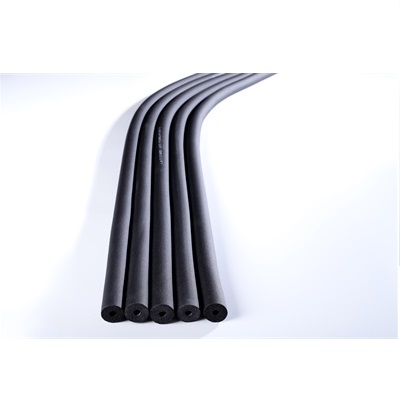

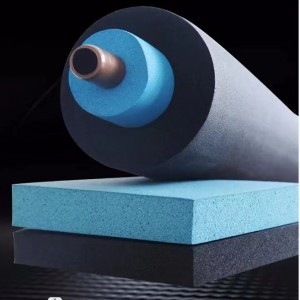

Colorful NBRPVC foaming insulation tube

Technical Data Sheet

|

Kingflex Technical Data |

|||

|

Property |

Unit |

Value |

Test Method |

|

Temperature range |

°C |

(-50 - 110) |

GB/T 17794-1999 |

|

Density range |

Kg/m3 |

45-65Kg/m3 |

ASTM D1667 |

|

Water vapor permeability |

Kg/(m.s.pa) |

≤0.91×10 ﹣¹³ |

DIN 52 615 BS 4370 Part 2 1973 |

|

μ |

- |

≥10000 |

|

|

Thermal Conductivity |

W/(m.k) |

≤0.030 (-20°C) |

ASTM C 518 |

|

≤0.032 (0°C) |

|||

|

≤0.036 (40°C) |

|||

|

Fire Rating |

- |

Class 0 & Class 1 |

BS 476 Part 6 part 7 |

|

Flame Spread and Smoke Developed Index |

|

25/50 |

ASTM E 84 |

|

Oxygen Index |

|

≥36 |

GB/T 2406,ISO4589 |

|

Water Absorption,%by Volume |

% |

20% |

ASTM C 209 |

|

Dimension Stability |

|

≤5 |

ASTM C534 |

|

Fungi resistance |

- |

Good |

ASTM 21 |

|

Ozone resistance |

Good |

GB/T 7762-1987 |

|

|

Resistance to U.V. and weather |

Good |

ASTM G23 |

|

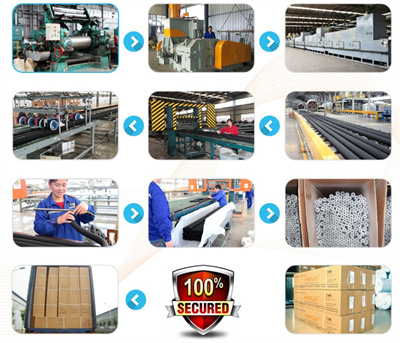

Production Procedure

Certification

Company

Growth in the construction industry and many other industrial segments, combined with concerns over rising energy costs and noise pollution, is fueling market demand foe thermal insualtion. With more than 42 years of dedicated experience in manufacturing and applications, Kingflex Insulation Company is riding on top of the wave.

Why Choose Kingflex

Product categories

-

Phone

-

E-mail

-

Whatsapp