Dienes Cryogenic Temperature Insulation Rubber Foam

Product Description:

Kingflex ULT

Density: 55-75kg/m³

Conductivity factor:

Average temperature-196℃----0.0127 W(m.k)

Average temperature-165℃----0.0169 W(m.k)

Average temperature-130℃----0.0186 W(m.k)

Average temperature-130℃----0.0212 W(m.k)

Average temperature-110℃----0.0231 W(m.k)

Average temperature-100℃----0.0242 W(m.k)

Kingflex LT

Density: 40-60kg/m³

Thermal Conductivity:

Average temperature0℃----0.033 W(m.k)

Average temperature-50℃----0.028W(m.k)

Recommend Operating Temperature: -50℃ to +105℃

Percentage of Close Area: >95%

Moisture Permeance Factor: <1.96x10g(m.s.Pa)

Wet Resistance Factor μ: 》10000z

Water Vapor Permiability Coefficient: 0.0039/h.m2(25mm thickness)

Tensile Strength MPa: 0℃--0.15; -40℃--0.218

Compressive Strength MPa: -40℃, ≤0.16.

Kingflex Cryogenic Multi-layer Composite Structure Description

With its benchmark product features and flexibility, our thermal insulation systems are the ideal choice for use in the oil and gas industry. Save energy and minimise the risk of corrosion under insulation (CUI). Benefit from easy handling and shipment. Reduce total installed time and drive savings. Plus, achieve optimal thermal performance in lightweight, reduced thickness industrial

insulation systems.

Product Main Advantages

. Cryogenic Systems can be fitted under compression so traditional open-cell, fibrous in-fill pieces for contraction and expansion joints are unnecessary

. The distinctive color of Kingflex ULT facilitates installation and inspection.

. Inner layers of Kinglfex ULT provide optimum mechanical properties at cryogenic temperatures, while outer layers of NBR-based Kingflex provide excellent thermal efficiency.

Our Company

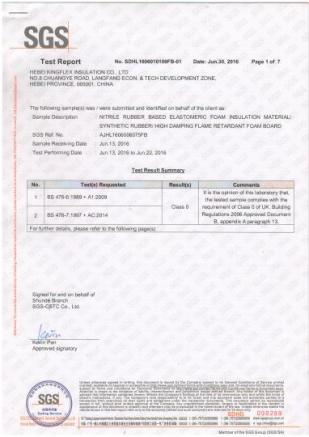

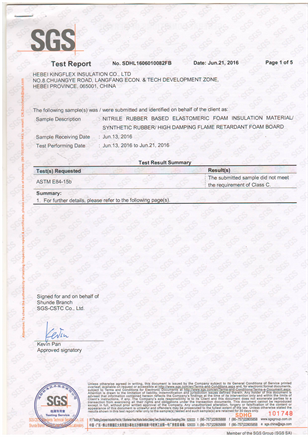

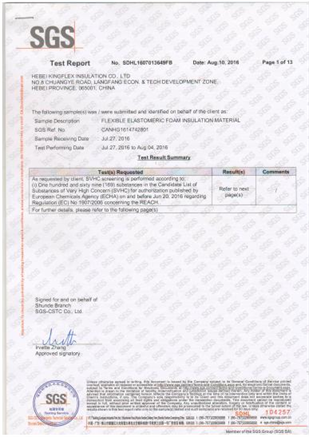

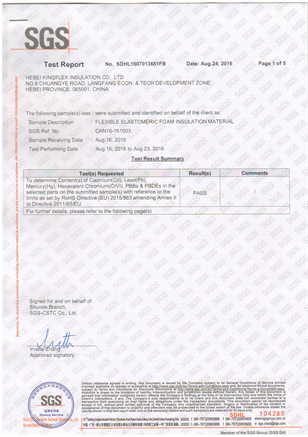

Company Certificate

We participate many exhibitions every year and have made many customers and friends from all over the world.

Part of our Certificates

Product categories

-

Phone

-

E-mail

-

Whatsapp