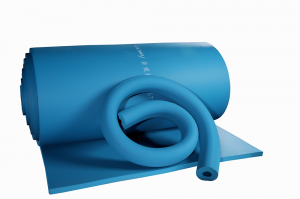

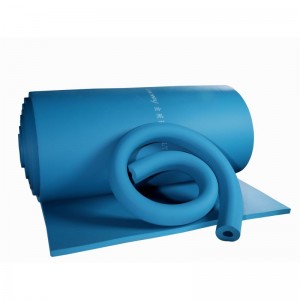

Elastomeric cryogenic insulation

Product Short Description

Main raw material: ULT—alkadiene polymer, Blue

LT—NBR/PVC, Black

Technical Data Sheet

|

Kingflex ULT Technical Data |

|||

|

Property |

Unit |

Value |

|

|

Temperature range |

°C |

(-200 - +110) |

|

|

Density range |

Kg/m3 |

60-80Kg/m3 |

|

|

Thermal Conductivity |

W/(m.k) |

≤0.028 (-100°C) |

|

|

|

|

≤0.021(-165°C) |

|

|

Fungi resistance |

- |

Good |

|

|

Ozone resistance |

|

Good |

|

|

Resistance to U.V. and weather |

|

Good |

|

Advantages of product

1.No need build-in moisture barrier

Kingflex flexible ultra low temperature insulation system does not need to install moisture-proof layer. Due to its unique closed cell structure and polymer blend formulation, low temperature elastomeric foam material have been highly resistant to water vapor permeation. This foam material provides continuous resistance to moisture penetration throughout the entire thickness of the product.

2.No need Built-in expansion joint

Kingflex flexible ULT insulation system does not require the use of fiber materials as expansion and expansion fillers. (This type of construction method is typical on rigid foam LNG pipes.)

On the contrary, it is only necessary to install the low temperature elastomeric material in each layer according to the recommended reserved length to solve the expansion joint problem required by the conventional system. The elasticity at low temperatures gives the material the characteristics of expansion and shrinkage in the longitudinal direction.

Our Company

Hebei Kingflex Insulation Co., Ltd. is founded by Kingway Group which is established in 1979. And Kingway Group company is a R&D, production, and selling in an energy saving and environmental protection of one manufacturer.

With 5 large automatic assembly lines, more than 600,000 cubic meters of annual production capacity, Kingway Group is specified as the designated production enterprise of thermal insulation materials for the National energy department, Ministry of electric power and Ministry of Chemical industry.

Company exhibition

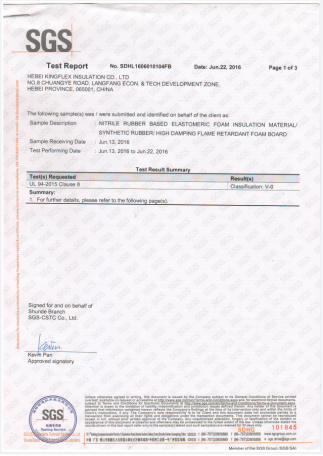

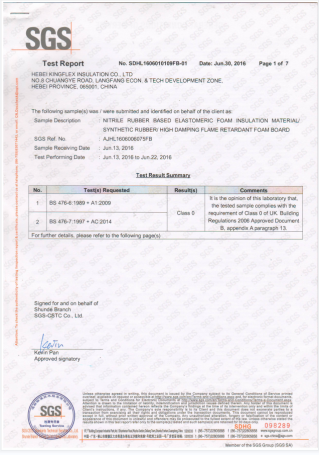

Certificate

Product categories

-

Phone

-

E-mail

-

Whatsapp