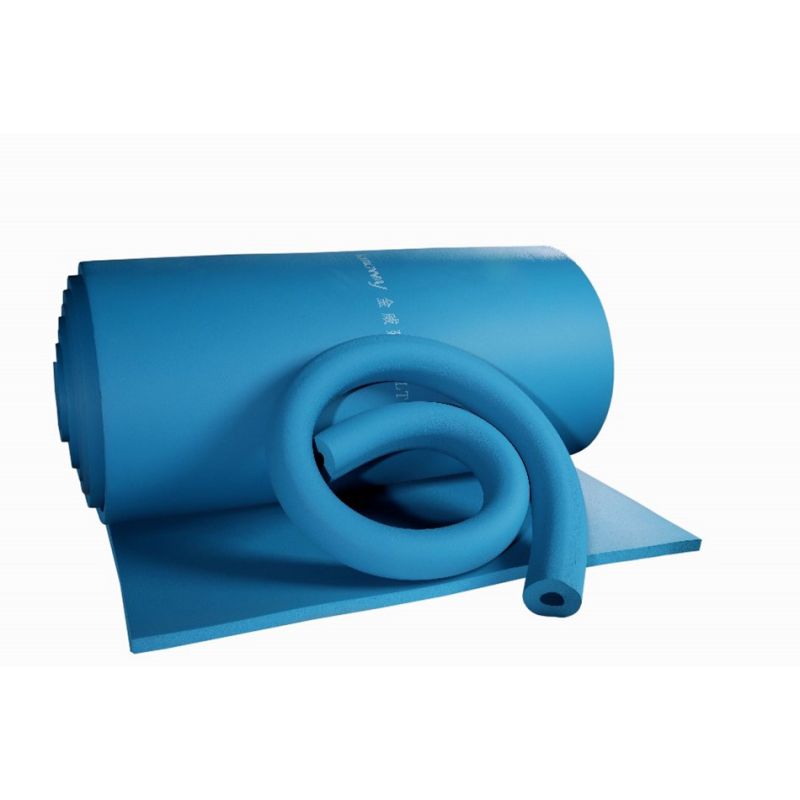

Elastomeric Insulation For Ultra Low Temperature System

Description

The system can be directly installed under the temperature as low as -110℃ on all piping equipment when the surface temperature of the pipe is lower than -100℃ and the pipeline usually has obvious repeated movement or vibration, it is necessary to a layer of wear-resistant film is laid on the inner surface to further strength the inner wall strength of the material to ensure the long-term adiabatic effect of frequent movement and vibration of the process pipeline under deep cooling.

Advantages of product

. Low thermal conductivity

. Low glass transtion temperature

. Easy installation even for complex shapes

. Less joint ensure the air lightness of the system and make the installation efficient

. Comprehensive cost is competitive

. Built-in moisture proof, no need to install the extra moisture barrier

. Without fiber, dust, CFC, HCFC

. No expansion joint is required.

Technical Data Sheet

|

Kingflex ULT Technical Data |

|||

|

Property |

Unit |

Value |

|

|

Temperature range |

°C |

(-200 - +110) |

|

|

Density range |

Kg/m3 |

60-80Kg/m3 |

|

|

Thermal Conductivity |

W/(m.k) |

≤0.028 (-100°C) |

|

|

≤0.021(-165°C) |

|||

|

Fungi resistance |

- |

Good |

|

|

Ozone resistance |

Good |

||

|

Resistance to U.V. and weather |

Good |

||

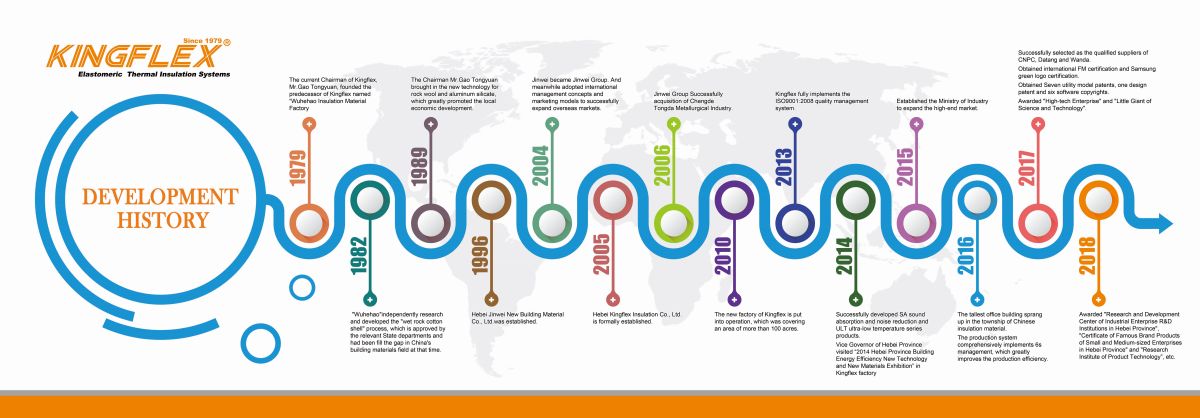

Our Company

Over four decades, Kingflex Insulation Company has grown from a single manufacturing plant in China to a global organization with product installation in over 60 countries. From the National Stadium in Beijing, to the high rises in New York, Singapore and Dubai, people around the world are enjoying the quality products from Kingflex.

Kingflex Insulation company was established in 2005. We are specialized in manufacturing and exporting rubber foam insulation products and glass wool insulation products.

Company exhibition

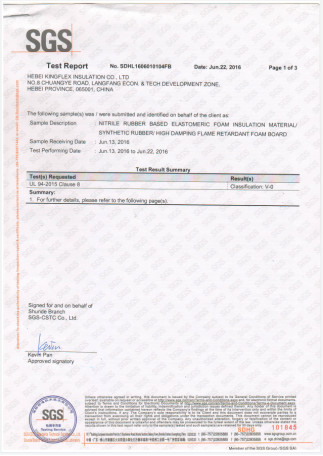

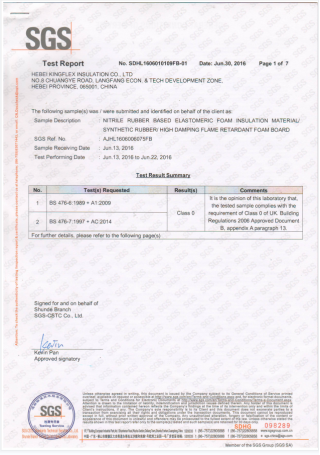

Part Of Our Certificates

Product categories

-

Phone

-

E-mail

-

Whatsapp