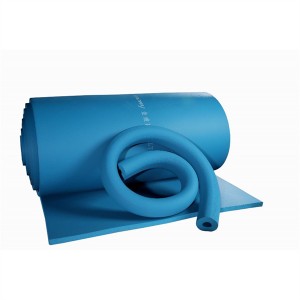

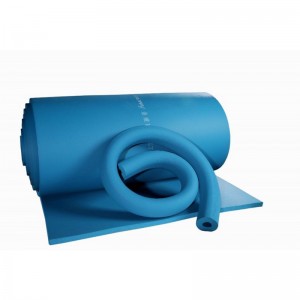

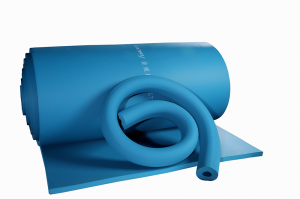

Elastomeric rubber foam insulation system for ultra low temperature

Kingflex thermal insulation system introduction

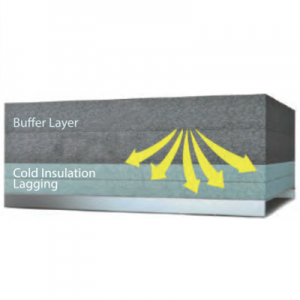

Kingflex insulation system has designed multiple thermal insulation systems for the oil and gas, petro and power plants markets. Working with alkadiene and NBR/PVC rubber materials, the multi-layer design is aimed at achieving an optimal balance of thermal performance; protection against water vapor ingress and reduced weight and thickness, our customers can rely on durable, cost and energy efficient insulation systems.

Proper attention provides better energy management, reduced operational failure

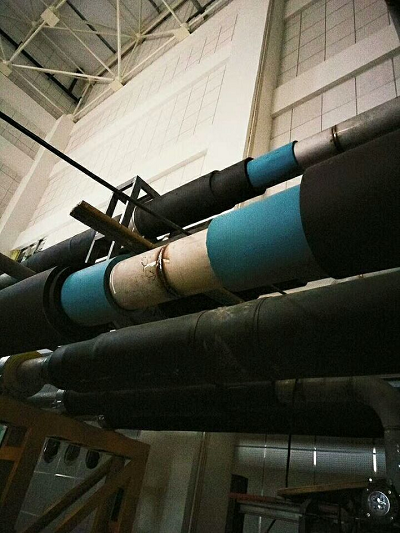

For optimum operation, industrial facilities such as power plants require mechanical insulation on pipes, ducts, tanks and equipment. Mechanical insulation in a power plant controls temperature variation to help limit heat gain or loss on surfaces operating at temperatures above or below ambient temperature. An experienced contractor typically manages installation of mechanical insulation in industrial environments.

Selecting the type of mechanical insulation to install begins with asking basic questions and understanding the scope of work. Mechanical insulation is divided into three different categories based on the level of heat it can withstand. Mechanical insulation contractors need to know the operating temperature range of the plant’s system before installing insulation. Knowing if a system is outdoors, indoors or both determines the type of protection needed to prevent damage from weather, a corrosive atmosphere, water or chemical exposure and other challenging conditions.

About Kingflex Insulation Company

Over four decades, Kingflex Insulation Company has grown from a single manufacturing plant in China to a global organization with product installation in over 60 countries. From the National Stadium in Beijing, to the high rises in New York, Singapore and Dubai, people around the world are enjoying the quality products from Kingflex.

Product categories

-

Phone

-

E-mail

-

Whatsapp