Factory For Heat Insulation Sheet Singapore - TUBE-1210-2 – Kingflex

Factory For Heat Insulation Sheet Singapore - TUBE-1210-2 – Kingflex Detail:

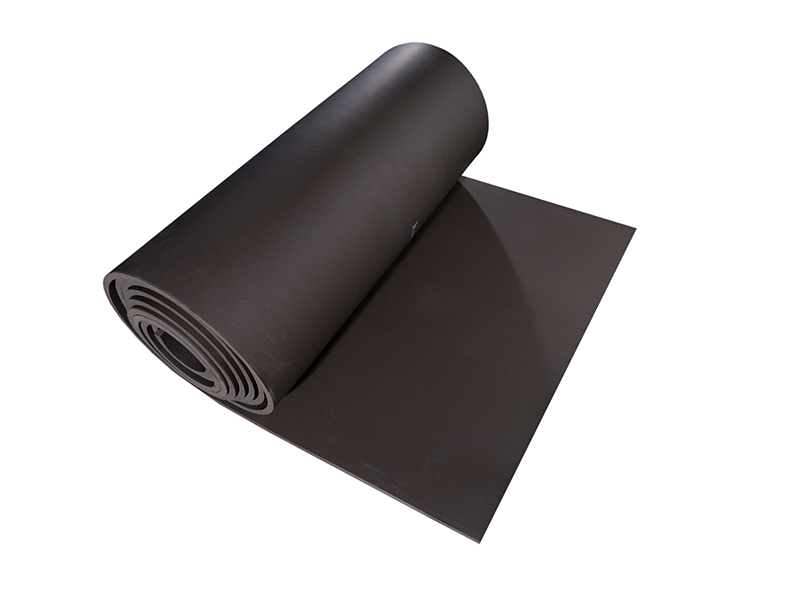

Descriptio

Kingflex rubber foam insulation product is idealy designed with a excellent fire and safety insulation performance according to the market demand. Kingflex adopt unique micro foaming techology. Product cells are uniformed and fined, have excellent heat preservation heat insulation performance and higher safety fireproof performance. It has achieved the highest fire certification of BS standard. It has reached the highest safety standards for fireproofing in the word, bring higher security for users.

● nominal wall thicknesses of 1/4”, 3/8″, 1/2″, 3/4″,1″, 1-1/4”, 1-1/2″ and 2” (6, 9, 13, 19, 25 , 32, 40 and 50mm)

● Standard Length with 6ft (1.83m) or 6.2ft(2m).

Technical Data Sheet

|

Kingflex Technical Data |

|||

|

Property |

Unit |

Value |

Test Method |

|

Temperature range |

°C |

(-50 – 110) |

GB/T 17794-1999 |

|

Density range |

Kg/m3 |

45-65Kg/m3 |

ASTM D1667 |

|

Water vapor permeability |

Kg/(m.s.pa) |

≤0.91×10 ﹣¹³ |

DIN 52 615 BS 4370 Part 2 1973 |

|

μ |

- |

≥10000 |

|

|

Thermal Conductivity |

W/(m.k) |

≤0.030 (-20°C) |

ASTM C 518 |

|

≤0.032 (0°C) |

|||

|

≤0.036 (40°C) |

|||

|

Fire Rating |

- |

Class 0 & Class 1 |

BS 476 Part 6 part 7 |

|

Flame Spread and Smoke Developed Index |

|

25/50 |

ASTM E 84 |

|

Oxygen Index |

|

≥36 |

GB/T 2406,ISO4589 |

|

Water Absorption,%by Volume |

% |

20% |

ASTM C 209 |

|

Dimension Stability |

|

≤5 |

ASTM C534 |

|

Fungi resistance |

- |

Good |

ASTM 21 |

|

Ozone resistance |

Good |

GB/T 7762-1987 |

|

|

Resistance to U.V. and weather |

Good |

ASTM G23 |

|

Advantage

♦ excellent thermal insulation- very low thermal conductivity

♦ excellent acoustuc insulation- can reduce noise and sound transmitting

♦ moisture resistant, fire resistant

♦ good strength to resist deformation

♦ closed cell structure

♦ ASTM/SGS/BS476/UL/GB Certified BS476, UL94, CE, AS1530, DIN, REACH and Rohs

Quality Inspection

Packaging & Shipping

Certificate

Exhibition

Product detail pictures:

Related Product Guide:

We usually perform being a tangible workforce making sure that we will give you the most beneficial excellent plus the finest selling price for Factory For Heat Insulation Sheet Singapore - TUBE-1210-2 – Kingflex , The product will supply to all over the world, such as: Portland, Tanzania, Malaysia, Our company has abundant strength and possesses a steady and perfect sales network system. We wish we could establish sound business relationships with all customers from at home and abroad on the basis of mutual benefits.

A good manufacturers, we have cooperated twice, good quality and good service attitude.

Product categories

-

Phone

-

E-mail

-

Whatsapp