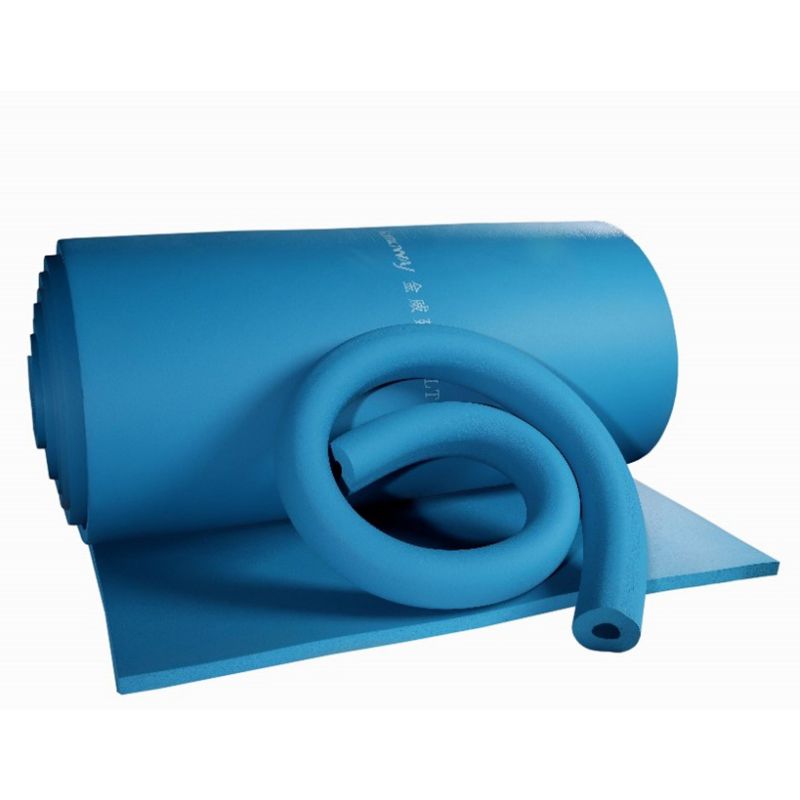

Flexible cryogenic insulation

Description

Kingflex flexible ultra-low temperature insulation system does not require a moisture barrier. Thanks to the unique closed cell structure and polymer mix formula, the elastic foam material of nitrile butadiene rubber has a high resistance to water vapor penetration. This foam material provides continuous resistance to moisture penetration throughout the thickness of the product.

Technical Data Sheet

|

Kingflex ULT Technical Data |

|||

|

Property |

Unit |

Value |

|

|

Temperature range |

°C |

(-200 - +110) |

|

|

Density range |

Kg/m3 |

60-80Kg/m3 |

|

|

Thermal Conductivity |

W/(m.k) |

≤0.028 (-100°C) |

|

|

≤0.021(-165°C) |

|||

|

Fungi resistance |

- |

Good |

|

|

Ozone resistance |

Good |

||

|

Resistance to U.V. and weather |

Good |

||

Advantages of product

No built-in moisture barrier is required

No built-in expansion joint

The temperature ranges from -200℃ to +125℃

It remains elastic at extremely low temperatures

Applications

Coal chemical MOT

Low temperature storage tank

FPSO floating production stroage oil unloading device

Industrial gas and agricultural chemical production plants

Platform pipe

Gas station

Ethylene pipe

LNG

Nitrogen plant

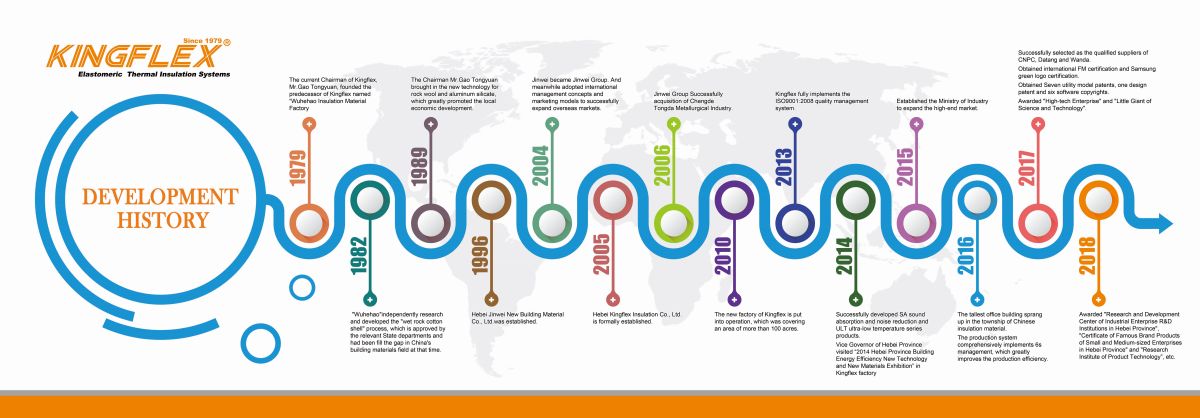

Our Company

Growth in the construction industry and many other industrial segments, combined with concerns over rising energy costs and noise pollution, is fueling market demand for thermal insulation. With more than four decades of dedicated experience in manufacturing and applications, Kingflex Insulation Company is riding on top of the wave.

With 5 large automatic assembly lines, more than 600,000 cubic meters of annual production capacity, Kingway Group is specified as the designated production enterprise of thermal insulation materials for the National energy department, Ministry of electric power and Ministry of Chemical industry.

Company exhibition

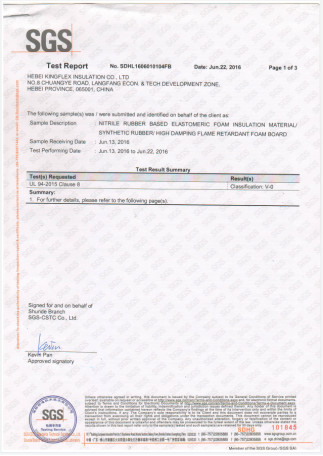

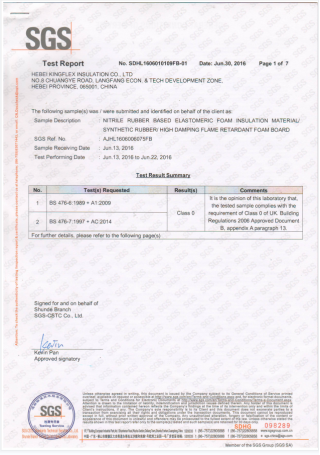

Part Of Our Certificates

Product categories

-

Phone

-

E-mail

-

Whatsapp