High Quality Rubber Foam Insulation Sheet Roll - cryogenic elastomeric foam rubber thermal insulation sheet roll – Kingflex

High Quality Rubber Foam Insulation Sheet Roll - cryogenic elastomeric foam rubber thermal insulation sheet roll – Kingflex Detail:

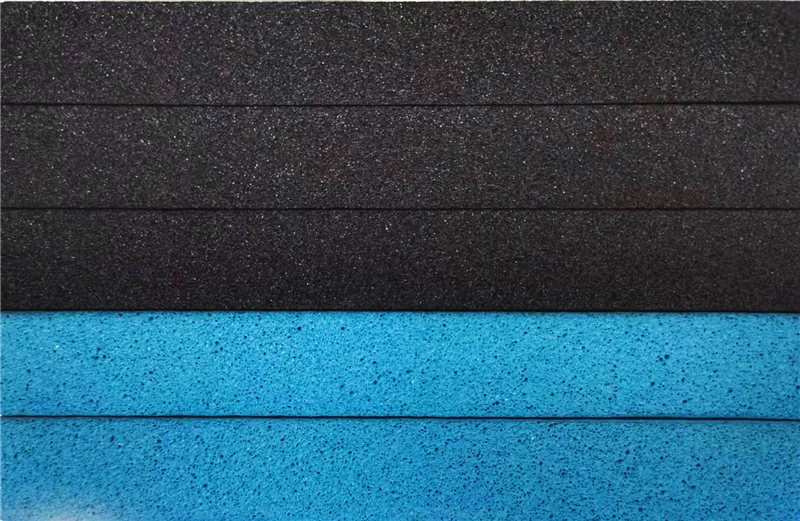

King flex flexible ultra-low temperature insulation system belongs to the multi-layer composite structure, is the most economical and reliable cooling system. The system can be directly installed under the temperature as low as -110°C on all piping equipment when the surface temperature of the pipe is lower than -100 °C and the pipeline usually has obvious repeated movement or vibration.

|

ULT Sheet standard size |

|||

|

Code |

Thickness(mm) |

Length(m) |

M2/Bag |

|

KF-ULT-25 |

25 |

8 |

8 |

Technical Data:

|

Performance |

Base Material |

Standard |

|

|

Kingflex ULT |

Kingflex LT |

||

|

Themal Conductivity |

(-100℃, 0.028 -165℃, 0.021) |

(0℃,0.033, -50 ℃, 0.028) |

ASTM C177 EN 12667 |

|

Density |

60-80 kg/m3 |

40-60 kg/m3 |

ASTM D 1622 |

|

Recommend Operating Temperature |

(-200℃ +125℃) |

(-50℃ +105℃) |

NA |

|

Percentage of Close Area |

> 95% |

>95% |

ASTM D 2856 |

|

Moisture Permeance Factor |

NA |

< 1.96 × 10g (m.s.Pa) |

ASTM E96 |

|

Wet Resistance Factor µ |

NA |

>10000 |

EN 12086 EN 13469 |

|

Water Vapor Permeability Coefficient |

NA |

0.0039g/h.m2 (25mm thickness) |

ASTM E96 |

|

PH |

≥ 8.0 |

≥ 8.0 |

ASTM C871 |

|

Tensile Strength MPa |

-100℃, 0.30 -165℃, 0.25 |

0℃, 0.15 -40℃, 0.218 |

ASTM D 1623 |

|

Compressive Strength MPa |

(-100℃, ≤0.37) |

(-40℃ ,≤0.16) |

ASTM D 1621 |

Advantage performance

* Low thermal conductivity

*Suitable for applications from -200 °C to +110 °C

*Low density and weight

*Cost effective

*Fewer seams to provide a faster and more secure installation

*Easily applied to awkward and difficult shapes

*Easily handled and transported

*Free of fibre and dust.

*Suitable for the oil and gas industry

*Minimised risk of corrosion under insulation

*Multi‐layered system provides exceptional thermal performance

*Ease of installation with reduced use of hazardous components

Parts of Projects

Tianjin Petrobest Energy Equipment Co., Ltd.

Mat Project Of Shandong Jin Ming Coal Water Chemical Group Co.,Ltd.

Glycol Project Of Lihuayi Group Co., Ltd.

Lng Natural Gas Station Of Enn Energy Holdings Limited.

Qingdao Sinopec

Lng Project Of Shanxi Xiangkuang Group Co., Ltd.

Integrated Eqipment System Of Air China

Ningxia Baofeng Energy Co.,Ltd.

Shanxi Yangquan Coal Industry(Group)Co.,Ltd

Shanxi Jin Ming Methanol Project

Applications

Product detail pictures:

Related Product Guide:

Well-run equipment, expert income workforce, and far better after-sales expert services; We are also a unified large family, anyone stick to the corporate value "unification, dedication, tolerance" for High Quality Rubber Foam Insulation Sheet Roll - cryogenic elastomeric foam rubber thermal insulation sheet roll – Kingflex , The product will supply to all over the world, such as: Zimbabwe, Kazakhstan, Slovenia, We believe with our consistently excellent service you can get the best performance and cost least goods from us for a long term . We commit to provide better services and create more value to all our customers. Hope we can create a better future together.

The company comply with the contract strict, a very reputable manufacturers, worthy a long-term cooperation.

Product categories

-

Phone

-

E-mail

-

Whatsapp