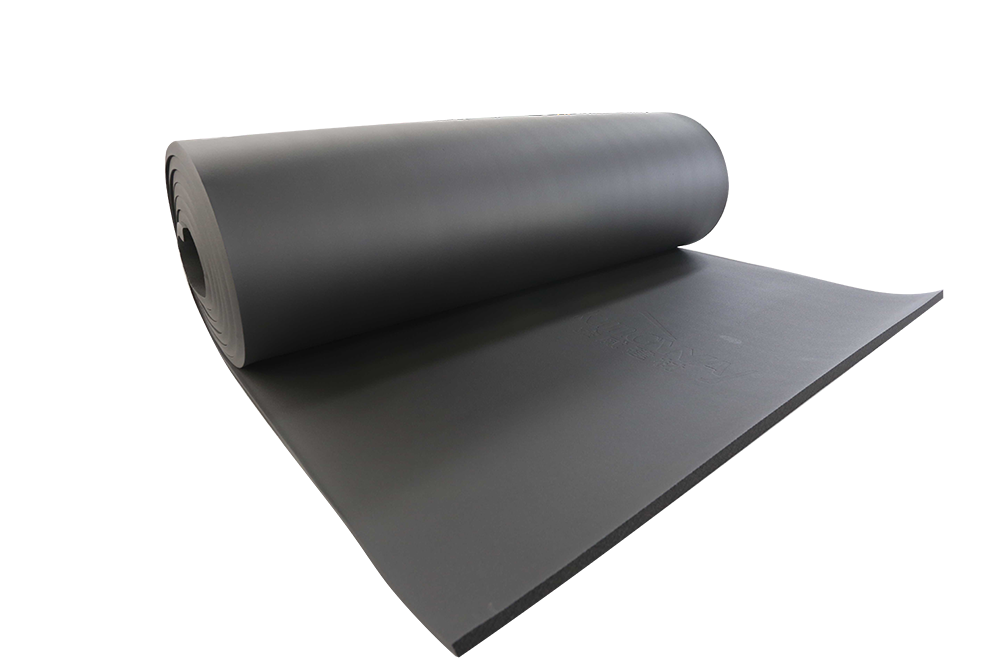

Kingflex Flexible Elastomeric NBR Foam Rolls

Description

Kingflex rubber foam insulation material is a flexible and robust insulation material which offers easy and fast installation process and nevertheless a long and durable lifespan.It is made with advanced technology and advanced full-automatic continuous production line imported from abroad,using polyvinyl Chloride (NBR,PVC) as main raw materials and other high quality auxiliary materials through foaming and so on special procedure.

Standard Dimension

|

Kingflex Dimension |

|||||||

|

Thickness |

Width 1m |

Width 1.2m |

Width 1.5m |

||||

|

Inches |

mm |

Size(L*W) |

㎡/Roll |

Size(L*W) |

㎡/Roll |

Size(L*W) |

㎡/Roll |

|

1/4" |

6 |

30 × 1 |

30 |

30 × 1.2 |

36 |

30 × 1.5 |

45 |

|

3/8" |

10 |

20 × 1 |

20 |

20 × 1.2 |

24 |

20 × 1.5 |

30 |

|

1/2" |

13 |

15 × 1 |

15 |

15 × 1.2 |

18 |

15 × 1.5 |

22.5 |

|

3/4" |

19 |

10 × 1 |

10 |

10 × 1.2 |

12 |

10 × 1.5 |

15 |

|

1" |

25 |

8 × 1 |

8 |

8 × 1.2 |

9.6 |

8 × 1.5 |

12 |

|

1 1/4" |

32 |

6 × 1 |

6 |

6 × 1.2 |

7.2 |

6 × 1.5 |

9 |

|

1 1/2" |

40 |

5 × 1 |

5 |

5 × 1.2 |

6 |

5 × 1.5 |

7.5 |

|

2" |

50 |

4 × 1 |

4 |

4 × 1.2 |

4.8 |

4 × 1.5 |

6 |

Technical Data Sheet

|

Kingflex Technical Data |

|||

|

Property |

Unit |

Value |

Test Method |

|

Temperature range |

°C |

(-50 - 110) |

GB/T 17794-1999 |

|

Density range |

Kg/m3 |

45-65Kg/m3 |

ASTM D1667 |

|

Water vapor permeability |

Kg/(m.s.pa) |

≤0.91×10 ﹣¹³ |

DIN 52 615 BS 4370 Part 2 1973 |

|

μ |

- |

≥10000 |

|

|

Thermal Conductivity |

W/(m.k) |

≤0.030 (-20°C) |

ASTM C 518 |

|

≤0.032 (0°C) |

|||

|

≤0.036 (40°C) |

|||

|

Fire Rating |

- |

Class 0 & Class 1 |

BS 476 Part 6 part 7 |

|

Flame Spread and Smoke Developed Index |

|

25/50 |

ASTM E 84 |

|

Oxygen Index |

|

≥36 |

GB/T 2406,ISO4589 |

|

Water Absorption,%by Volume |

% |

20% |

ASTM C 209 |

|

Dimension Stability |

|

≤5 |

ASTM C534 |

|

Fungi resistance |

- |

Good |

ASTM 21 |

|

Ozone resistance |

Good |

GB/T 7762-1987 |

|

|

Resistance to U.V. and weather |

Good |

ASTM G23 |

|

Application

1. Low thermal conductivity

Cellular foam structure, low thermal conductivity, high surface heat release coefficient, good thermal insulation effect

2. Closed-cell foam structure

Closed pore structure, independent bubble holes are not connected, forming a closed vapor barrier layer, which can form multiple barriers to water vapor molecules, even if the pipe surface is damaged, it can still achieve vapor isolation

3. Good flexibility

Rubber foam rolls are flexible, suitable for all kinds of bends and irregular pipes, convenient for construction, saving work and materials.

Our Company

Company exhibition

Certificate

Product categories

-

Phone

-

E-mail

-

Whatsapp