Kingflex rubber foam insulation tube

Product Description:

Kingflex rubber foam products of our company are produced by imported high-end technology and automatic continuous equipment. We have developed a rubber foam insulation material with excellent performance through in-depth research. The major materials we use are NBR/PVC.

Technical Data Sheet

|

Kingflex Technical Data |

|||

|

Property |

Unit |

Value |

Test Method |

|

Temperature range |

°C |

(-50 - 110) |

GB/T 17794-1999 |

|

Density range |

Kg/m3 |

45-65Kg/m3 |

ASTM D1667 |

|

Water vapor permeability |

Kg/(m.s.pa) |

≤0.91×10 ﹣¹³ |

DIN 52 615 BS 4370 Part 2 1973 |

|

μ |

- |

≥10000 |

|

|

Thermal Conductivity |

W/(m.k) |

≤0.030 (-20°C) |

ASTM C 518 |

|

|

|

≤0.032 (0°C) |

|

|

|

|

≤0.036 (40°C) |

|

|

Fire Rating |

- |

Class 0 & Class 1 |

BS 476 Part 6 part 7 |

|

Flame Spread and Smoke Developed Index |

|

25/50 |

ASTM E 84 |

|

Oxygen Index |

|

≥36 |

GB/T 2406,ISO4589 |

|

Water Absorption,%by Volume |

% |

20% |

ASTM C 209 |

|

Dimension Stability |

|

≤5 |

ASTM C534 |

|

Fungi resistance |

- |

Good |

ASTM 21 |

|

Ozone resistance |

|

Good |

GB/T 7762-1987 |

|

Resistance to U.V. and weather |

|

Good |

ASTM G23 |

Advantages of product

Moulding air conditioner copper pipe insulation soft foam rubber tube closed cell rubber foam tube FOR IRAQ

NBR PVC Rubber foam insulation material

Close-cell structure, smooth surface, light weight, excellent heat and thermal insulation performance.

High quality rubber foam insulation material reduce heat loss, save the energy, waterproof, with low thermal conductivity and also

keeps the process temperature stable.

With strong adhesive for easy install.

Our Company

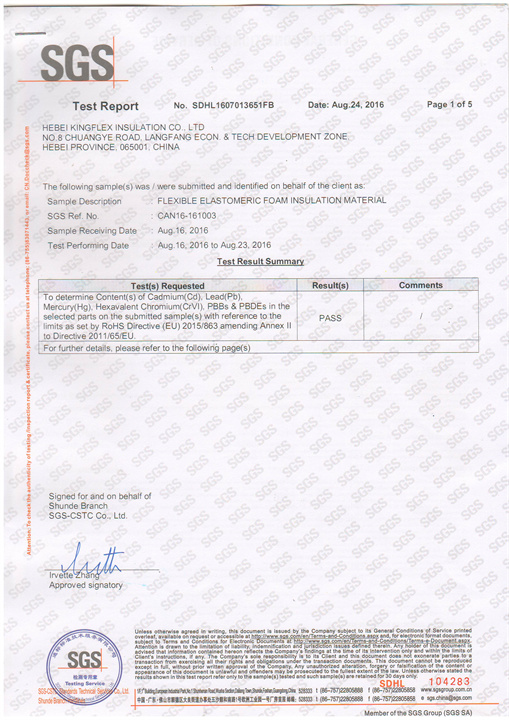

Company Certificate

Part of our Certificates

Product categories

-

Phone

-

E-mail

-

Whatsapp