Kingflex Thermal Insulation Tubes are closed-cell

Description

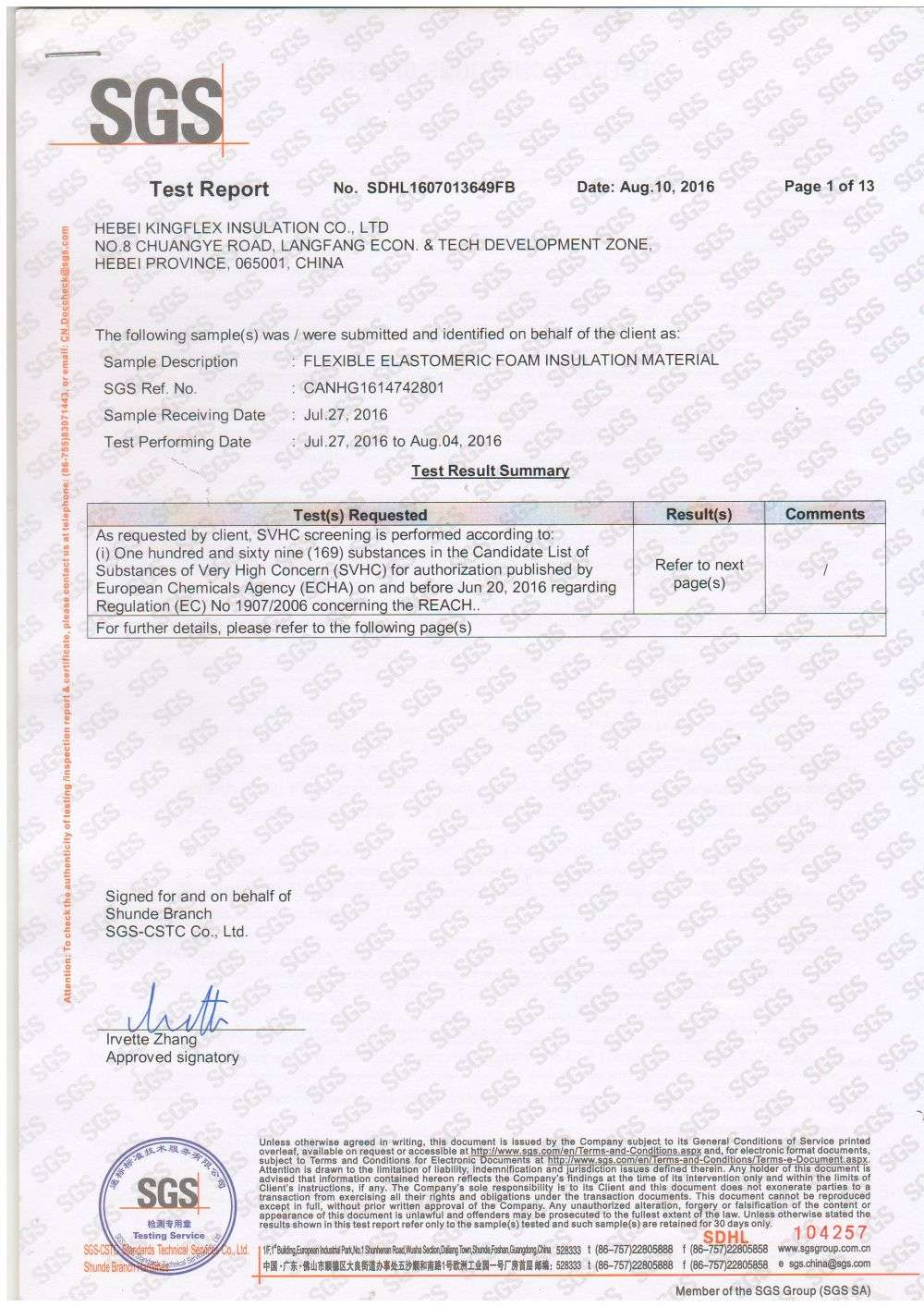

Kingflex Thermal Insulation Tubes not only are they environmentally friendly, they pose no harm to human health, they have zero Ozone Depletion Potential (ODP), Global Warming Potential (GWP) of less than five, and a low Volatile Organic Compound (VOC) of less than 6 µg/m2/hr in 24 hours. The elimination of chlorofluorocarbons (CFC) and hydro chlorofluorocarbons (HCFC) from the production process while complying with LEED requirements make BOLNFLEX Thermal Insulation Tubes ideal for use in projects that need optimal air conditioning, refrigeration, chilled water pipes, and hot water pipes thermal insulation.

Technical Data Sheet

|

Kingflex Technical Data |

|||

|

Property |

Unit |

Value |

Test Method |

|

Temperature range |

°C |

(-50 - 110) |

GB/T 17794-1999 |

|

Density range |

Kg/m3 |

45-65Kg/m3 |

ASTM D1667 |

|

Water vapor permeability |

Kg/(m.s.pa) |

≤0.91×10 ﹣¹³ |

DIN 52 615 BS 4370 Part 2 1973 |

|

μ |

- |

≥10000 |

|

|

Thermal Conductivity |

W/(m.k) |

≤0.030 (-20°C) |

ASTM C 518 |

|

≤0.032 (0°C) |

|||

|

≤0.036 (40°C) |

|||

|

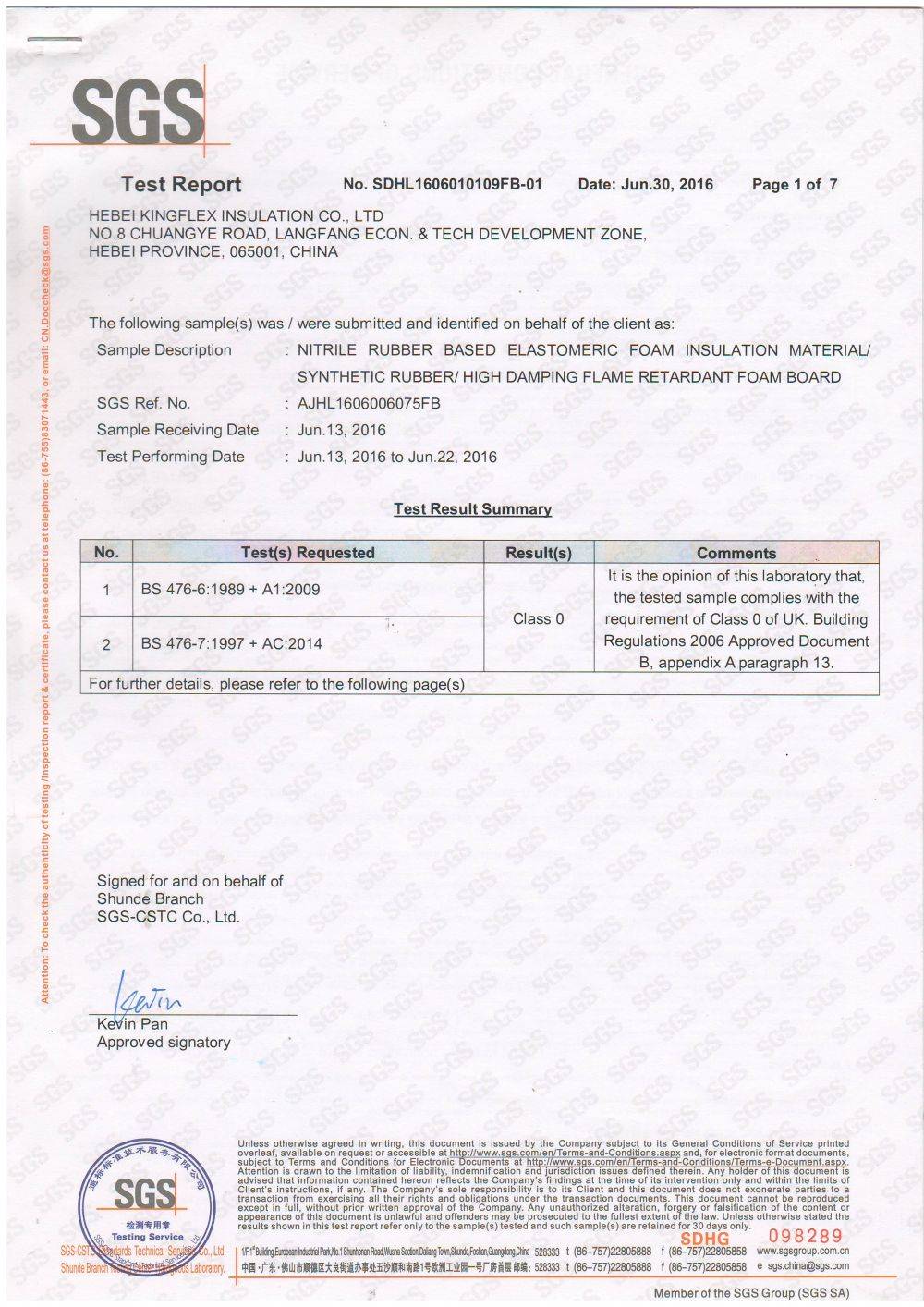

Fire Rating |

- |

Class 0 & Class 1 |

BS 476 Part 6 part 7 |

|

Flame Spread and Smoke Developed Index |

|

25/50 |

ASTM E 84 |

|

Oxygen Index |

|

≥36 |

GB/T 2406,ISO4589 |

|

Water Absorption,%by Volume |

% |

20% |

ASTM C 209 |

|

Dimension Stability |

|

≤5 |

ASTM C534 |

|

Fungi resistance |

- |

Good |

ASTM 21 |

|

Ozone resistance |

Good |

GB/T 7762-1987 |

|

|

Resistance to U.V. and weather |

Good |

ASTM G23 |

|

Advantages of product

Improve the energy efficiency of the building

Reduce transmission of exterior sound to the interior of the building

Absorb reverberating sounds within the building

Provide thermal efficiency

Keep the building warmer in winter and cooler in summer

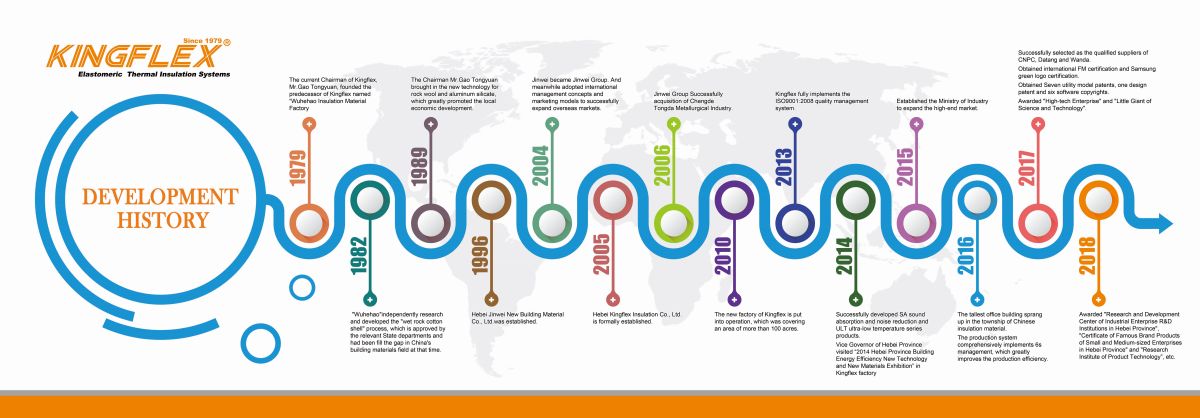

Our Company

Company exhibition

Certificate

Product categories

-

Phone

-

E-mail

-

Whatsapp