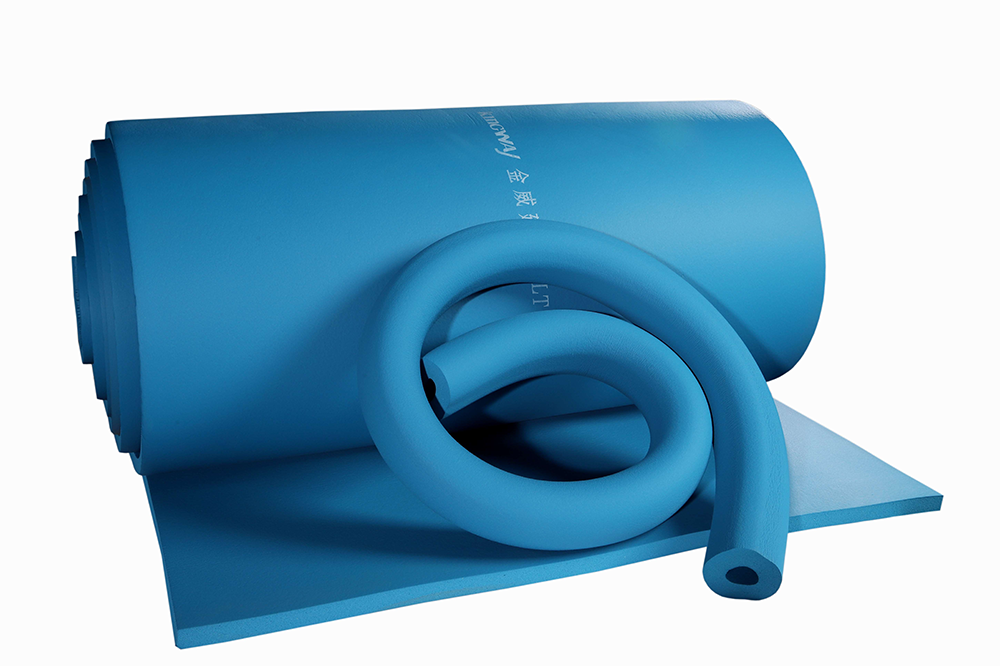

NBR/PVC Rubber Foam Insulation For Cryogenic System

Description

Kingflex flexible ultra-low temperature insulation system does not require a moisture barrier. Thanks to the unique closed cell structure and polymer mix formula, the elastic foam material of nitrile butadiene rubber has a high resistance to water vapor penetration. This foam material provides continuous resistance to moisture penetration throughout the thickness of the product.

Standard Dimension

|

Kingflex Dimension |

|||

|

Inches |

mm |

Size(L*W) |

㎡/Roll |

|

3/4" |

20 |

10 × 1 |

10 |

|

1" |

25 |

8 × 1 |

8 |

Technical Data Sheet

|

Property |

Base material |

Standard |

|

|

Kingflex ULT |

Kingflex LT |

Test Method |

|

|

Thermal Conductivity |

-100°C, 0.028 -165°C, 0.021 |

0°C, 0.033 -50°C, 0.028 |

ASTM C177

|

|

Density Range |

60-80Kg/m3 |

40-60Kg/m3 |

ASTM D1622 |

|

Recommend Operation Temperature |

-200°C to 125°C |

-50°C to 105°C |

|

|

Percentage Of Close Areas |

>95% |

>95% |

ASTM D2856 |

|

Moisture Performance Factor |

NA |

<1.96x10g(m.m.Pa) |

ASTM E 96 |

|

Wet resistance Factor μ |

NA |

>10000 |

EN12086 EN13469 |

|

Water Vapor Permeability Coefficient |

NA |

0.0039g/h.m2 (25mm thickness) |

ASTM E 96 |

|

PH |

≥8.0 |

≥8.0 |

ASTM C871 |

|

Tensile Strength Mpa |

-100°C, 0.30 -165°C, 0.25 |

0°C, 0.15 -50°C, 0.218 |

ASTM D1623 |

|

Comprssive Strength Mpa |

-100°C, ≤0.3 |

-40°C, ≤0.16 |

ASTM D1621 |

Application

Low temperature storage tank; industrial gas and agricultural chemical production plants; platform pipe; gas station; nitrogen plant...

Our Company

Kingflex was invested by Kingway Group. Growth in the construction and remodeling industries, combined with concerns over rising energy costs and noise pollution, are fueling market demand for thermal insulation. With 40 years of dedicated experience in manufacturing and applications, KWI is riding on top of the wave. KWI is focusing on all verticals in the commercial and industrial market. KWI scientists and engineers are always at the forefront of the industry. New products and applications are continuously rolled out to make people's living more comfortable and businesses more profitable.

Company exhibition

Certificate

Product categories

-

Phone

-

E-mail

-

Whatsapp