Reasonable price for Pipe Insulation Thickness Table - Rubber plastic plate 1 – Kingflex

Reasonable price for Pipe Insulation Thickness Table - Rubber plastic plate 1 – Kingflex Detail:

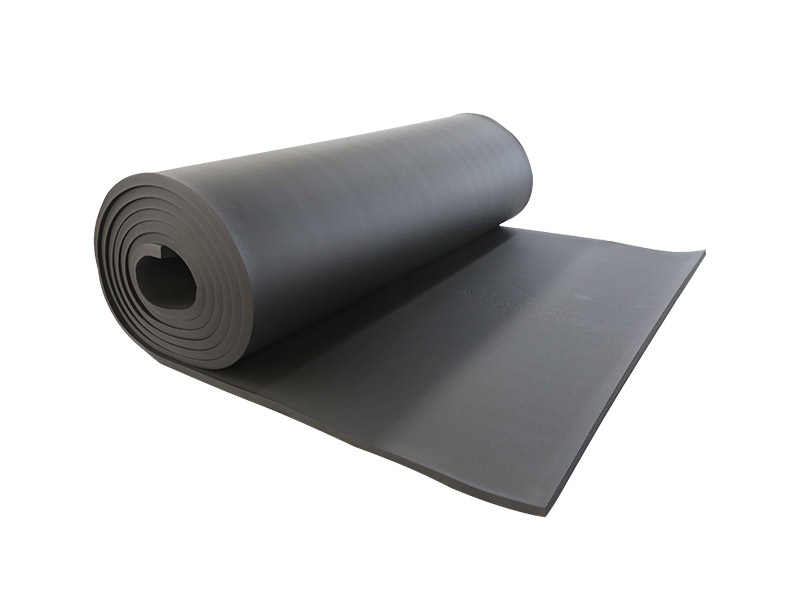

Product Description

Standard Dimension

|

Kingflex Dimension |

|||||||

|

Thickness |

Width 1m |

Width 1.2m |

Width 1.5m |

||||

|

Inches |

mm |

Size(L*W) |

㎡/Roll |

Size(L*W) |

㎡/Roll |

Size(L*W) |

㎡/Roll |

|

1/4″ |

6 |

30 × 1 |

30 |

30 × 1.2 |

36 |

30 × 1.5 |

45 |

|

3/8″ |

10 |

20 × 1 |

20 |

20 × 1.2 |

24 |

20 × 1.5 |

30 |

|

1/2″ |

13 |

15 × 1 |

15 |

15 × 1.2 |

18 |

15 × 1.5 |

22.5 |

|

3/4″ |

19 |

10 × 1 |

10 |

10 × 1.2 |

12 |

10 × 1.5 |

15 |

|

1″ |

25 |

8 × 1 |

8 |

8 × 1.2 |

9.6 |

8 × 1.5 |

12 |

|

1 1/4″ |

32 |

6 × 1 |

6 |

6 × 1.2 |

7.2 |

6 × 1.5 |

9 |

|

1 1/2″ |

40 |

5 × 1 |

5 |

5 × 1.2 |

6 |

5 × 1.5 |

7.5 |

|

2″ |

50 |

4 × 1 |

4 |

4 × 1.2 |

4.8 |

4 × 1.5 |

6 |

Technical Data Sheet

|

Kingflex Technical Data |

|||

|

Property |

Unit |

Value |

Test Method |

|

Temperature range |

°C |

(-50 – 110) |

GB/T 17794-1999 |

|

Density range |

Kg/m3 |

45-65Kg/m3 |

ASTM D1667 |

|

Water vapor permeability |

Kg/(m.s.pa) |

≤0.91×10 ﹣¹³ |

DIN 52 615 BS 4370 Part 2 1973 |

|

μ |

- |

≥10000 |

|

|

Thermal Conductivity |

W/(m.k) |

≤0.030 (-20°C) |

ASTM C 518 |

|

≤0.032 (0°C) |

|||

|

≤0.036 (40°C) |

|||

|

Fire Rating |

- |

Class 0 & Class 1 |

BS 476 Part 6 part 7 |

|

Flame Spread and Smoke Developed Index |

|

25/50 |

ASTM E 84 |

|

Oxygen Index |

|

≥36 |

GB/T 2406,ISO4589 |

|

Water Absorption,%by Volume |

% |

20% |

ASTM C 209 |

|

Dimension Stability |

|

≤5 |

ASTM C534 |

|

Fungi resistance |

- |

Good |

ASTM 21 |

|

Ozone resistance |

Good |

GB/T 7762-1987 |

|

|

Resistance to U.V. and weather |

Good |

ASTM G23 |

|

Company Profile

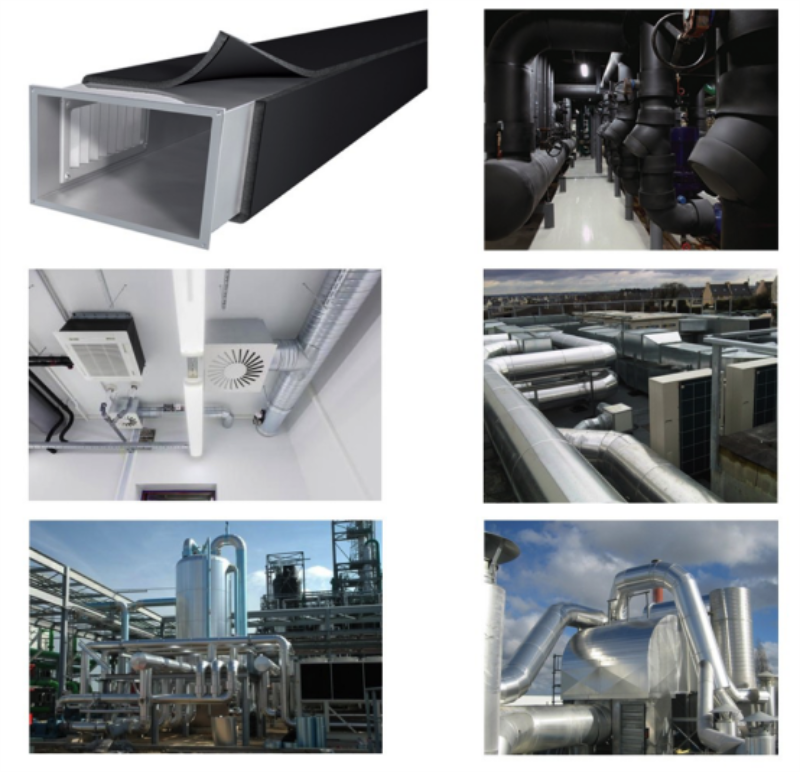

Kingflex Insulation Co.,Itd. is a fast growing enterprise and won the High-tech enterprises of Hebei Province , who is specialized in Rubber Insulation Foam. Our products include Thermal Insulation, Sound Insulation, Adhesive insulation series, and so on. They are widely used in the industry of Construction, Vehicle, Chemical storage and Transportation.

Production Line

Kingflex Rubber foam Material is soft heat-insulating, heat-preservation and energy conservation materials made with advanced technology at home and advanced full-automatic continuous production line imported from abroad, using butyronitrile rubber with best performance and polyvinyl Chloride (NBR,PVC) as main raw materials and other high quality auxiliary materials through foaming and so on special procedure.

Applications

Certification

Product detail pictures:

Related Product Guide:

We have been proud from the higher consumer gratification and wide acceptance due to our persistent pursuit of high quality both on product or service and service for Reasonable price for Pipe Insulation Thickness Table - Rubber plastic plate 1 – Kingflex , The product will supply to all over the world, such as: UAE, Oman, Qatar, Due to our strict pursues in quality, and after-sale service, our product gets more and more popular around the world. Many clients came to visit our factory and place orders. And there are also many foreign friends who came for sight seeing, or entrust us to buy other stuff for them. You are most welcome to come to China, to our city and to our factory!

With a positive attitude of "regard the market, regard the custom, regard the science", the company works actively to do research and development. Hope we have a future business relationships and achieving mutual success.

Product categories

-

Phone

-

E-mail

-

Whatsapp