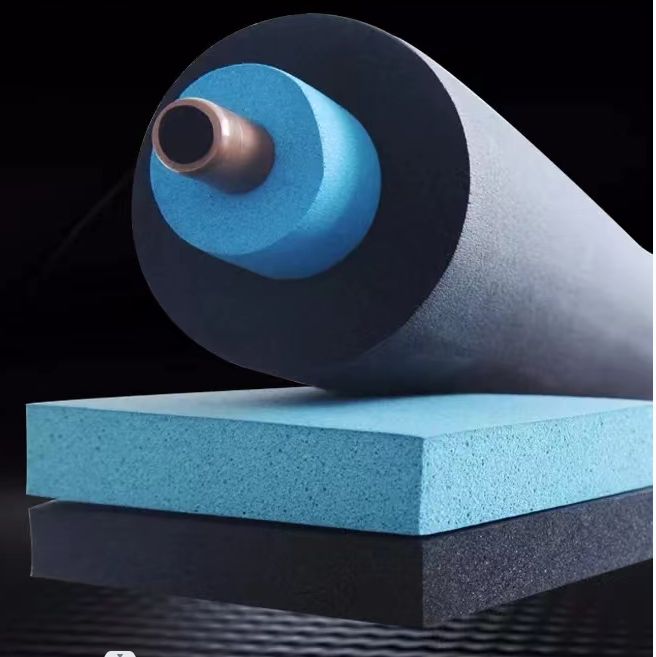

Rubber Foam Insulation For Ultra Low Temperature Pipeline System

Description

This solution system overcomes stress at low temperatures and provides maximum mechanical performance.

Standard Dimension

|

Kingflex Dimension |

||||

|

Inches |

mm |

Size(L*W) |

㎡/Roll |

|

|

3/4" |

20 |

10 × 1 |

10 |

|

|

1" |

25 |

8 × 1 |

8 |

|

Technical Data Sheet

|

Property |

Base material |

Standard |

|

|

Kingflex ULT |

Kingflex LT |

Test Method |

|

|

Thermal Conductivity |

-100°C, 0.028 -165°C, 0.021 |

0°C, 0.033

-50°C, 0.028 |

ASTM C177

|

|

Density Range |

60-80Kg/m3 |

40-60Kg/m3 |

ASTM D1622 |

|

Recommend Operation Temperature |

-200°C to 125°C |

-50°C to 105°C |

|

|

Percentage Of Close Areas |

>95% |

>95% |

ASTM D2856 |

|

Moisture Performance Factor |

NA |

<1.96x10g(m.m.Pa) |

ASTM E 96 |

| Wet resistance Factor

μ |

NA |

>10000 |

EN12086 EN13469 |

|

Water Vapor Permeability Coefficient |

NA |

0.0039g/h.m2 (25mm thickness) |

ASTM E 96 |

|

PH |

≥8.0 |

≥8.0 |

ASTM C871 |

|

Tensile Strength Mpa |

-100°C, 0.30 -165°C, 0.25 |

0°C, 0.15

-50°C, 0.218 |

ASTM D1623 |

|

Comprssive Strength Mpa |

-100°C, ≤0.3 |

-40°C, ≤0.16 |

ASTM D1621 |

Advantages of product

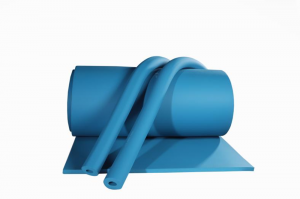

Kingflex ULT is a flexible, high density and mechanically robust, closed cell cryogenic thermal insulation material based on extruded elastomeric foam. The product has been specially developed for use on the import/export pipelines and process areas of liquefied natural gas(LNG) facilities. It is part of Kingflex Cryogenic multi-layer configuration, providing low temperature flexibility to the system.

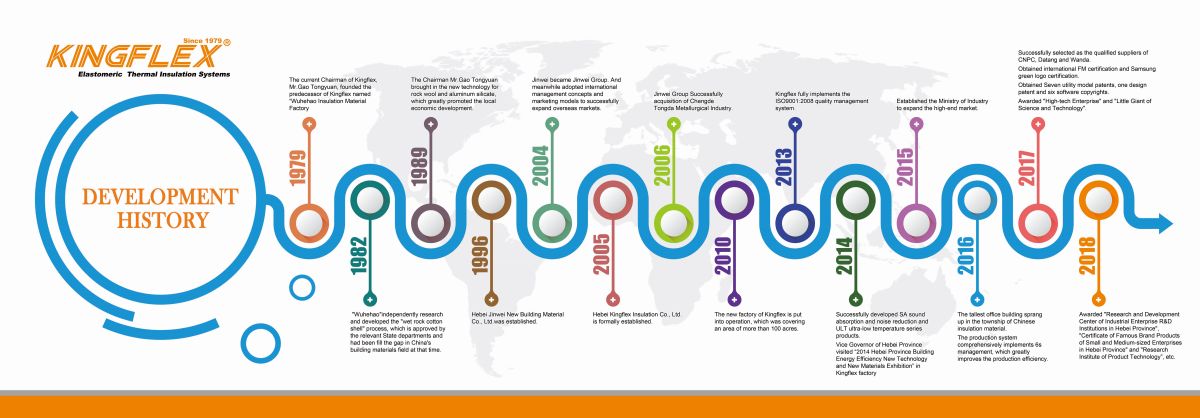

Our Company

Over four decades, Kingflex Insulation Company has grown from a single manufacturing plant in China to a global organization with product installation in over 50 countries. From the National Stadium in Beijing, to the high rises in New York, Singapore and Dubai, people around the world are enjoying the quality products from Kingflex.

Company exhibition

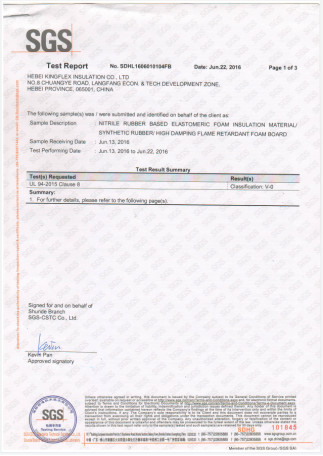

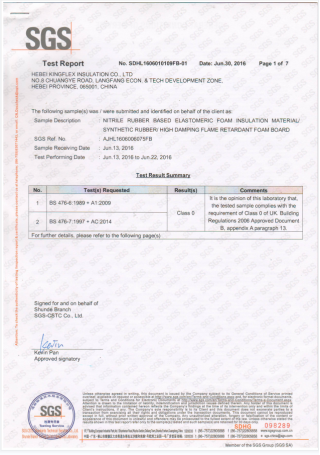

Part Of Our Certificates

Product categories

-

Phone

-

E-mail

-

Whatsapp