Super Lowest Price Piping Insulation Procedure - elastomeric NBR/PVC rubber foam thermal insulation pipe tubing – Kingflex

Super Lowest Price Piping Insulation Procedure - elastomeric NBR/PVC rubber foam thermal insulation pipe tubing – Kingflex Detail:

Black, red, green and yellow color are all available.

The expanded closed-cell structure of Kingflex Rubber Foam Insulation Tube makes it an efficient insulation. It is manufactured without the use of CFC’s, HFC’s or HCFC’s. It is also formaldehyde free, low VOCs, fiber free, dust free and resists mold and mildew. Kingflex Rubber Foam Insulation Tube can be made with special antimicrobial product protection for added defense against mold on the insulation.

|

Technical Data |

|||

|

Property |

Unit |

Value |

Test Method |

|

Temperature range |

°C |

(-50 – 110) |

GB/T 17794-1999 |

|

Density range |

Kg/m3 |

45-65Kg/m3 |

ASTM D1667 |

|

Water vapor permeability |

Kg/(m.s.pa) |

≤0.91×10 ﹣¹³ |

DIN 52 615 BS 4370 Part 2 1973 |

|

μ |

- |

≥10000 |

|

|

Thermal Conductivity |

W/(m.k) |

≤0.030 (-20°C) |

ASTM C 518 |

|

≤0.032 (0°C) |

|||

|

≤0.036 (40°C) |

|||

|

Fire Rating |

- |

Class 0 & Class 1 |

BS 476 Part 6 part 7 |

|

Flame Spread and Smoke Developed Index |

25/50 |

ASTM E 84 |

|

|

Oxygen Index |

≥36 |

GB/T 2406,ISO4589 |

|

|

Water Absorption,%by Volume |

% |

20% |

ASTM C 209 |

|

Dimension Stability |

≤5 |

ASTM C534 |

|

|

Fungi resistance |

- |

Good |

ASTM 21 |

|

Ozone resistance |

Good |

GB/T 7762-1987 |

|

|

Resistance to U.V. and weather |

Good |

ASTM G23 |

|

Standard Dimensions

|

NO. |

Copper Tube |

Steel Pipe |

Internal Φ mm |

9mm ·3/8″FF |

13mm ·1/2″HH |

19mm ·3/4″MM |

25mm ·1″RR |

|||||||

|

Nom. ID Inches |

Nom. ID Inches |

I.PS. Inches |

Φ External mm |

Φ Nominal mm |

Ref. Wall*ID |

Lengths (2m) per cart |

Ref. Wall*ID |

Lengths (2m) per cart |

Ref. Wall*ID |

Lengths (2m) per cart |

Ref. Wall*ID |

Lengths (2m) per cart |

||

|

1 |

1/4 |

6.4 |

7.1 8.5 |

9*06 |

170 |

13*6 |

90 |

19*6 |

50 |

25*6 |

35 |

|||

|

2 |

3/8 |

9.5 |

1/8 |

10.2 |

6 |

11.1 12.5 |

9*09 |

135 |

13*10 |

80 |

19*10 |

40 |

25*10 |

25 |

|

3 |

1/2 |

12.7 |

12.5 |

13.1 14.5 |

9*13 |

115 |

13*13 |

65 |

19*13 |

40 |

25*13 |

25 |

||

|

4 |

5/8 |

15.9 |

1/4 |

13.5 |

8 |

16.1 17.5 |

9*16 |

90 |

13*16 |

60 |

19*16 |

35 |

25*16 |

20 |

|

5 |

3/4 |

19.1 |

19.0 20.5 |

9*19 |

76 |

13*19 |

45 |

19*19 |

30 |

25*20 |

20 |

|||

|

6 |

7/8 |

22.0 |

1/2 |

21.3 |

15 |

23.0 24.5 |

9*22 |

70 |

13*22 |

40 |

19*22 |

30 |

25*22 |

20 |

|

7 |

1 |

25.4 |

25.0 |

26.0 27.5 |

9*25 |

55 |

13*25 |

40 |

19*25 |

25 |

25*25 |

20 |

||

|

8 |

1 1/8 |

28.6 |

3/4 |

26.9 |

20 |

29.0 30.5 |

9*28 |

50 |

13*28 |

36 |

19*28 |

24 |

25*28 |

18 |

|

9 |

32.0 |

32.5 35.0 |

9*32 |

40 |

13*32 |

30 |

19*32 |

20 |

25*32 |

15 |

||||

|

10 |

1 3/8 |

34.9 |

1 |

33.7 |

25 |

36.0 38.0 |

9*35 |

36 |

13*35 |

30 |

19*35 |

20 |

25*35 |

15 |

|

11 |

1 1/2 |

38.0 |

38.0 |

39.0 41.0 |

9*38 |

36 |

13*38 |

24 |

19*38 |

17 |

25*38 |

12 |

||

|

12 |

1 5/8 |

41.3 |

1 1/2 |

42.4 |

32 |

43.5 45.5 |

9*42 |

30 |

13*42 |

25 |

19*42 |

17 |

25*42 |

12 |

|

13 |

44.5 |

44.5 |

45.5 47.5 |

9*45 |

25 |

13*45 |

20 |

19*45 |

16 |

25*45 |

12 |

|||

|

14 |

1 7/8 |

48.0 |

1 1/2 |

48.3 |

40 |

49.5 51.5 |

9*48 |

25 |

13*48 |

20 |

19*48 |

15 |

25*48 |

12 |

|

15 |

2 1/8 |

54.0 |

54.0 |

55.0 57.0 |

9*54 |

25 |

13*54 |

20 |

19*54 |

15 |

25*54 |

10 |

||

|

16 |

2 |

57.1 |

57.0 |

58.0 60.0 |

13*57 |

18 |

19*57 |

12 |

25*57 |

9 |

||||

|

17 |

2 3/8 |

60.3 |

2 |

60.3 |

50 |

61.5 63.5 |

13*60 |

18 |

19*60 |

12 |

25*60 |

9 |

||

|

18 |

2 5/8 |

67.0 |

67.5 70.5 |

13*67 |

15 |

19*67 |

10 |

25*67 |

8 |

|||||

|

19 |

3 |

76.2 |

2 1/2 |

76.1 |

65 |

77.0 79.5 |

13*76 |

12 |

19*76 |

10 |

25*76 |

6 |

||

|

20 |

3 1/8 |

80.0 |

13*80 |

12 |

19*80 |

10 |

25*80 |

6 |

||||||

|

21 |

3 1/2 |

88.9 |

3 |

88.9 |

80 |

90.5 93.5 |

13*89 |

10 |

19*89 |

8 |

25*89 |

6 |

||

|

22 |

4 1/4 |

108.0 |

108.0 |

108 111 |

13*108 |

6 |

19*108 |

6 |

25*108 |

5 |

||||

|

Tolerance: Thickness |

士 1.3mm |

士 2.0mm |

士 2.4mm |

士 2.4mm |

||||||||||

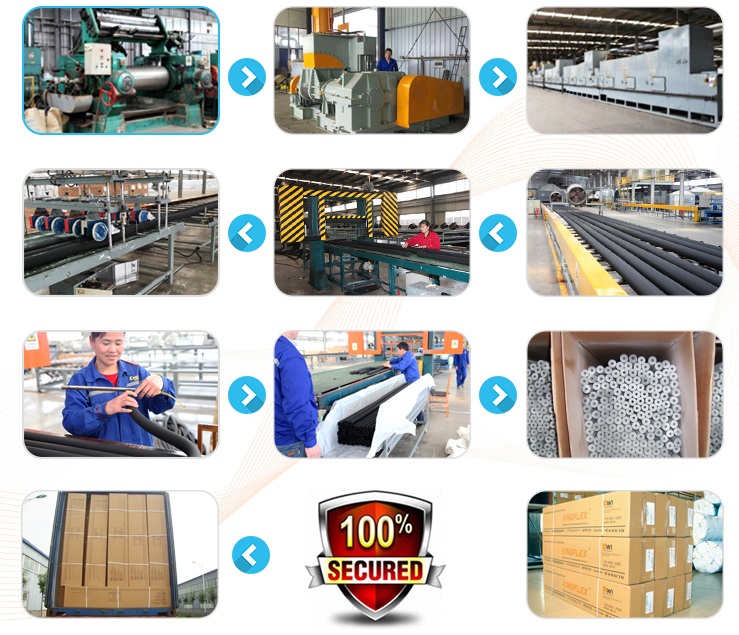

Production process

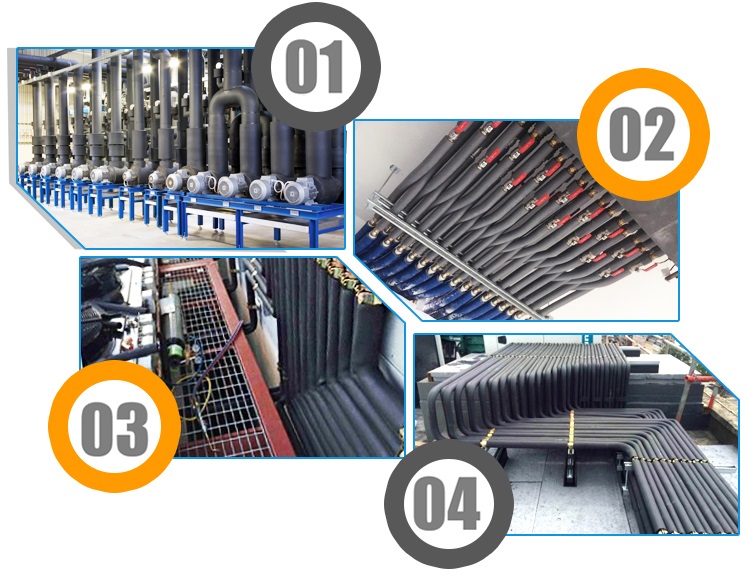

Application

Kingflex Rubber Foam Insulation Tube is used to retard heat gain and control condensation drip from chilled-water and refrigeration systems. It also efficiently reduces heat flow for hot-water plumbing and liquid-heating and dual-temperature piping. The recommended temperature usage range for Kingflex Rubber Foam Insulation Tube is -297°F to +220°F(-183°C to +105°C).

For use on cold pipes, Kingflex Rubber Foam Insulation Tube thicknesses have been calculated to control condensation on the insulation outer surface, as shown in the table of thickness recommendations.

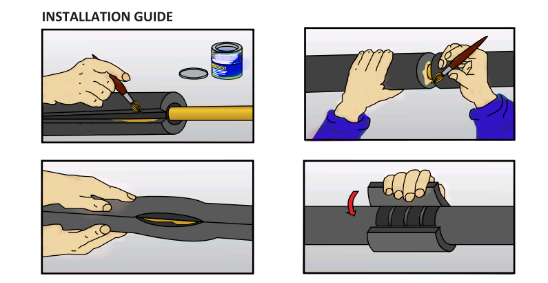

Installation

Product detail pictures:

Related Product Guide:

Gaining purchaser gratification is our company's aim eternally. We're going to make great initiatives to create new and top-quality products, satisfy your exclusive prerequisites and supply you with pre-sale, on-sale and after-sale solutions for Super Lowest Price Piping Insulation Procedure - elastomeric NBR/PVC rubber foam thermal insulation pipe tubing – Kingflex , The product will supply to all over the world, such as: Lyon, Luxembourg, Croatia, Our company insists on the principle of "Quality First, Sustainable Development", and takes "Honest Business, Mutual Benefits" as our developable goal. All members sincerely thank all old and new customers' support. We will keep working hard and offering you the highest-quality products and service.

This is a very professional and honest Chinese supplier, from now on we fell in love with the Chinese manufacturing.

Product categories

-

Phone

-

E-mail

-

Whatsapp