Thermal Insulation Rubber Foam Sheet

Description

It's widely used in the heat-insulation and heat-preservation of various pipes and equipments, such as the central air conditioners, separate air conditioners, construction, medicine, chemical and appliance. It was the best option for the customer who strives for perfection

Standard Dimension

|

Kingflex Dimension |

|||||||

|

Thickness |

Width 1m |

Width 1.2m |

Width 1.5m |

||||

|

Inches |

mm |

Size(L*W) |

㎡/Roll |

Size(L*W) |

㎡/Roll |

Size(L*W) |

㎡/Roll |

|

1/4" |

6 |

30 × 1 |

30 |

30 × 1.2 |

36 |

30 × 1.5 |

45 |

|

3/8" |

10 |

20 × 1 |

20 |

20 × 1.2 |

24 |

20 × 1.5 |

30 |

|

1/2" |

13 |

15 × 1 |

15 |

15 × 1.2 |

18 |

15 × 1.5 |

22.5 |

|

3/4" |

19 |

10 × 1 |

10 |

10 × 1.2 |

12 |

10 × 1.5 |

15 |

|

1" |

25 |

8 × 1 |

8 |

8 × 1.2 |

9.6 |

8 × 1.5 |

12 |

|

1 1/4" |

32 |

6 × 1 |

6 |

6 × 1.2 |

7.2 |

6 × 1.5 |

9 |

|

1 1/2" |

40 |

5 × 1 |

5 |

5 × 1.2 |

6 |

5 × 1.5 |

7.5 |

|

2" |

50 |

4 × 1 |

4 |

4 × 1.2 |

4.8 |

4 × 1.5 |

6 |

Technical Data Sheet

|

Kingflex Technical Data |

|||

|

Property |

Unit |

Value |

Test Method |

|

Temperature range |

°C |

(-50 - 110) |

GB/T 17794-1999 |

|

Density range |

Kg/m3 |

45-65Kg/m3 |

ASTM D1667 |

|

Water vapor permeability |

Kg/(m.s.pa) |

≤0.91×10 ﹣¹³ |

DIN 52 615 BS 4370 Part 2 1973 |

|

μ |

- |

≥10000 |

|

|

Thermal Conductivity |

W/(m.k) |

≤0.030 (-20°C) |

ASTM C 518 |

|

≤0.032 (0°C) |

|||

|

≤0.036 (40°C) |

|||

|

Fire Rating |

- |

Class 0 & Class 1 |

BS 476 Part 6 part 7 |

|

Flame Spread and Smoke Developed Index |

|

25/50 |

ASTM E 84 |

|

Oxygen Index |

|

≥36 |

GB/T 2406,ISO4589 |

|

Water Absorption,%by Volume |

% |

20% |

ASTM C 209 |

|

Dimension Stability |

|

≤5 |

ASTM C534 |

|

Fungi resistance |

- |

Good |

ASTM 21 |

|

Ozone resistance |

Good |

GB/T 7762-1987 |

|

|

Resistance to U.V. and weather |

Good |

ASTM G23 |

|

Advantages of product

Closed cell structure

Prevent condensation

Excellent thermal efficiency

Suitable for low temperature applications

Suitable for cooling and heating systems

Resistant to bacteria

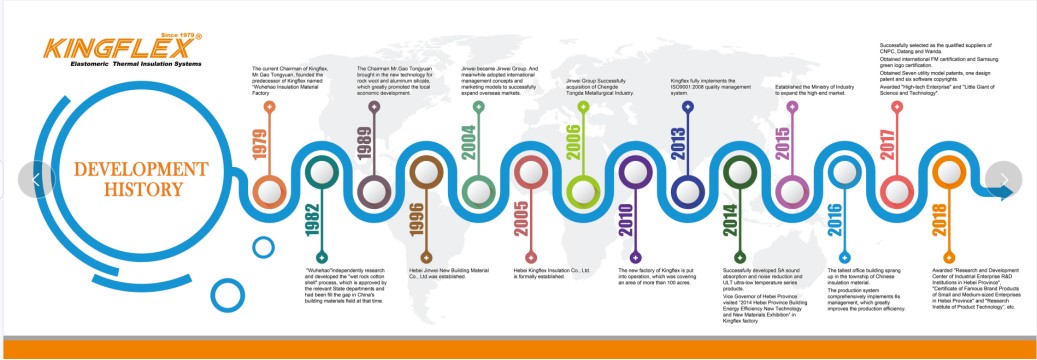

Our Company

Company exhibition

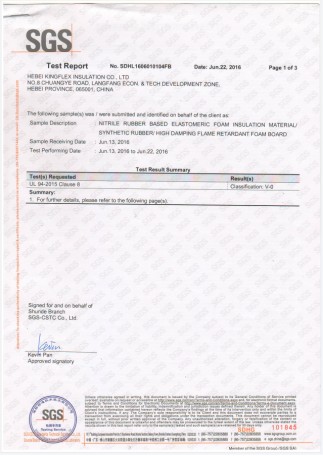

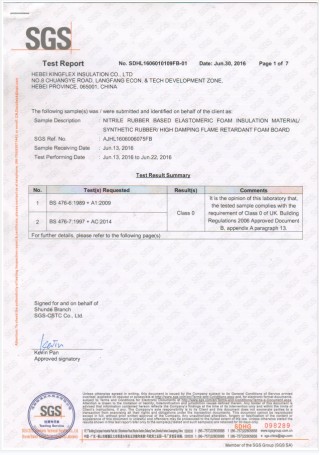

Certificate

Product categories

-

Phone

-

E-mail

-

Whatsapp